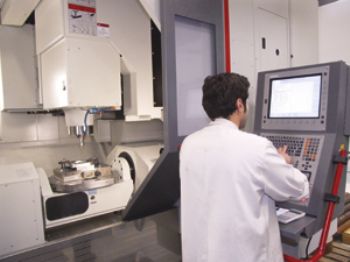

Installing a Quaser UX 600 five-axis CNC machining centre with a swivelling rotary table has given Swindon-based Metalite the capability for ‘one-hit’ component production.

Supplied by the Engineering Technology Group (

www.engtechgroup.com), this is currently the largest Quaser vertical five-axis machine operating in the UK. Its ability to accommodate workpieces weighing up to 300kg makes it a welcome addition to Metalite’s machine inventory, which is largely based on Hardinge milling machines.

\Managing director Lee James says: “We have established a niche in the UK market for the design and manufacture of mould tools, most of which are used in the medical and food packaging industries. However, when capacity allows, we are also happy to undertake more general-purpose high-precision sub-contract machining.”

Operations manager Michael Watts says: “The five Hardinge XR 1000 three-axis VMCs are the workhorses of our operations, but an injection mould tool may require multiple ops on a number of different machines — typically starting on a three-axis VMC, then onto a five-axis and finally horizontal boring on another machine.

“Given our heavy workload, this can cause problems with machine scheduling. The full five-axis capacity of the UX 600 is helping to overcome these bottlenecks, because we can now manufacture tools to an advanced stage in a single set-up.”