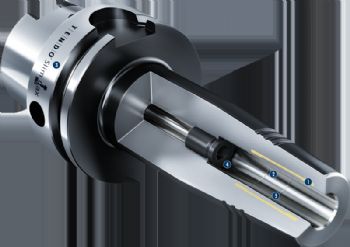

With the Tendo Slim 4ax hydraulic expansion tool-holder from Newport Pagnell-based Schunk Intec Ltd (

www.gb.schunk.com), it is possible to combine the complete outside geometry of heat-shrink mountings (according to DIN 69882-8) with the company’s hydraulic expansion technology.

The slim precision mounting makes it suitable for use in series production, particularly in the automotive industry.

It was designed with axial operations in mind and ‘shows its strength’ when milling close to interfering contours, as well as when undertaking counter-sinking and reaming on five-axis machining centres.

Moreover, the design of the hydraulic expansion tool-holder results in less deflection of the tool.

The Tendo Slim 4ax has a run-out accuracy of less than 0.003mm at an unclamped length of 2.5xD and a balance grade of G2.5 at 25,000rev/min.

In the first phase of its introduction, 10, 12, 14 and 20mm-diameter units are available for HSK-A63 interfaces.