Vollmer’s VPulse 500 1000 Edition drew the crowds at the recent Ligna Show in HannoverVollmer

Vollmer’s VPulse 500 1000 Edition drew the crowds at the recent Ligna Show in HannoverVollmer has launched its VPulse 500 1000 Edition, a highly efficient wire erosion machine that represents a significant leap forward in the manufacturing and maintenance of polycrystalline diamond (PCD) tipped tools. Building upon the proven success of the QWD series, the VPulse 500 1000 Edition is a limited edition machine that offers new levels of precision and efficiency.

The exclusive VPulse 500 1000 Edition will be available for a limited time, and has been introduced to celebrate the milestone that 1,000 Vollmer wire erosion machines installed worldwide. This exclusive machine edition features the company’s powerful EDM generator, an HR Automation system for increased tool capacity, oscillation eroding technology, customised maintenance intervals, PCD residue detection, and much more – all as part of the limited time offer.

The new VPulse EDM erosion generator delivers either higher material removal rates or optimised surface quality to perfectly support a diverse range of machining objectives. The integrated technology database significantly simplifies operation by providing preconfigured parameters that enhance user-friendliness. Operators can quickly select appropriate material-specific machining programmes, while the database can be expanded to meet specific customer requirements.

Optimum machining performanceThe VPulse 500 is a complete solution that incorporates everything required for manufacturing and maintaining PCD-tipped tools. The machine’s ‘state of the art’ control technology delivers optimum machining performance through simultaneous path interpolation along five CNC axes, enabling measurement and erosion within a single clamping operation. The machine accommodates machining with unsupported clamping and offers an optional counterpoint unit for machining between centres. Various interfaces provide flexibility for different workpieces.

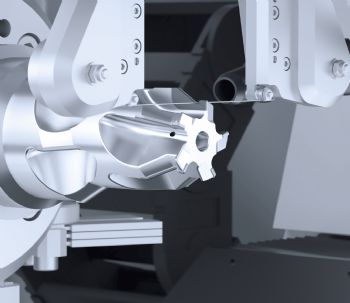

Rotary Tools being eroded on the VPulse 500

Rotary Tools being eroded on the VPulse 500Vollmer has developed an operating concept that prioritises human-machine interaction. The approach incorporates a flexible height-adjustable and tilting control panel that ensures operators maintain optimum views of both the display and machine work area. Operation occurs via touchscreen or mouse, with user-friendly menu navigation ensuring complex tasks can be performed with minimal training. Simple information retrieval provides access to essential programme and machine parameters, while new documentation and analysis options support faster process optimisation.

The VPulse 500 1000 Edition integrates the proven ExProg programming system, combining renowned strengths with new qualities. The intuitive user interface enables easy application, while profiles can be divided into any number of sub-contours for enhanced machining flexibility.

The VPulse 500 1000 Edition provides fine contours and exceptionally sharp cutting edges cost-effectively while ensuring maximum process reliability. In metal applications, particularly within the automotive and aerospace sectors, manufacturers gain from the machine’s capacity to produce complex tool geometries reliably and productively. For woodworking sector tool manufacturers requiring exceptional profile accuracy, the VPulse 500 1000 Edition consistently delivers dependable results.

Unmanned operationThrough its intelligent HR automation solution, the VPulse 500 1000 Edition can operate entirely unmanned for extended periods, including weekends. Its internal automation system accommodates up to 16 tools, each weighing up to 20kg, with a maximum diameter of 300mm and a length of 500mm. In addition, an HC5 automation solution is available for manufacturers requiring greater capacity, providing 28 and 64 tool storage options.

The VPulse 500 1000 Edition embodies three core advantages: maximum precision through groundbreaking five-axis kinematics, enhanced productivity via high-performance control systems combined with the new VPulse EDM erosion generator, and easier handling through innovative operating concepts and improved human-machine interaction.