Tezmaksan Robot Technologies

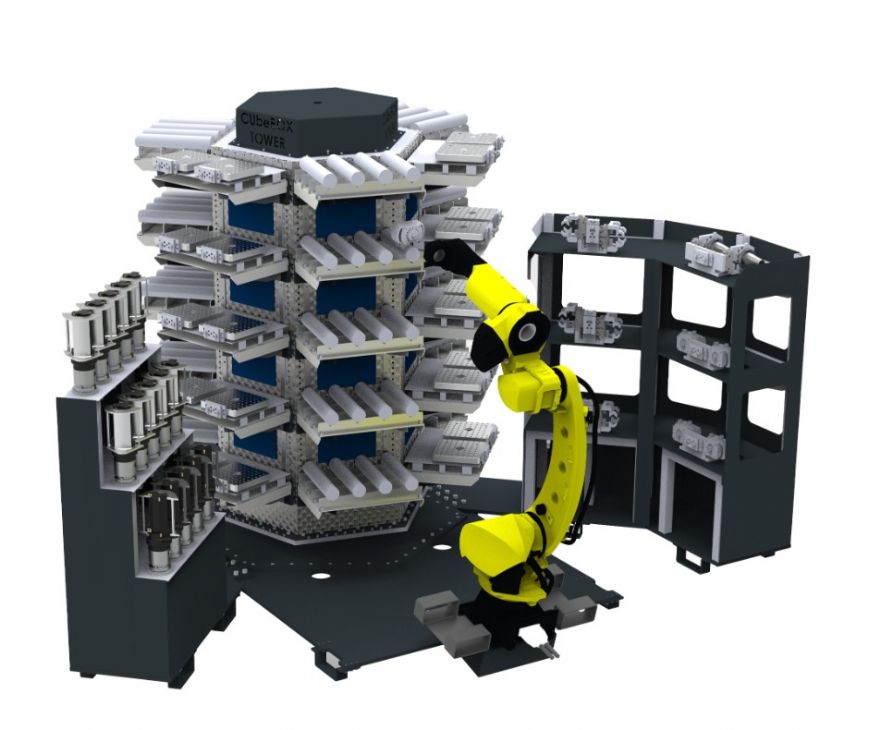

Tezmaksan Robot Technologies, a leading European manufacturer of CNC automation systems, has introduced the CubeBOX Tower — a scalable automatic toolchanger designed to increase production capacity and enable continuous, unmanned machining. With its compact hexagonal tower design, the system delivers exceptional storage density and rapid part changeovers, allowing manufacturers to automate multiple CNC machines seamlessly and maintain uninterrupted production during extended runs.

Engineered for large-scale machining environments, CubeBOX Tower is tailored for sectors where reliability and round-the-clock output are essential, including automotive, aerospace, energy, defence and medical component manufacturing. Its tower-type configuration supports CNC machine tending for both milling and turning applications and can be adapted to serve one or more machines simultaneously.

The hexagon-shaped tower mechanism performs automated part loading, pallet changing and tool exchanges without manual intervention. Each face of the tower accommodates a distinct setup, enabling users to prepare multiple jobs in advance and switch between them instantly. This design significantly boosts throughput while ensuring consistent quality across shifts.

Tezmaksan CEO Hakan Aydogdu said: “The CubeBOX Tower is a direct response to manufacturers’ need for scalable, high-capacity automation. Its hexagonal tower system allows higher storage density and quick changeovers, helping businesses achieve uninterrupted manufacturing across multiple CNC machines — all within a compact footprint.”

One of the system’s standout features is its high load-bearing capacity, which sets it apart from standard CNC tending solutions. Capable of handling heavier workpieces and larger tool sets, CubeBOX Tower offers a clear advantage for production lines managing cast parts, structural components or heavy alloys.

The structure is engineered for high-capacity performance, incorporating a rotating design that supports continuous production with automated part, pallet and vice changes. Depending on configuration, CubeBOX Tower can accommodate up to 48 pallets measuring 250 x 250mm or 24 pallets at 600 x 600mm, each with a maximum shelf load of 200kg.

At the heart of the system lies RoboCAM+, Tezmaksan’s proprietary control software, which transforms CAD drawings into executable robotic motions. Operators benefit from a user-friendly touch-screen interface that eliminates complex robot programming and reduces setup times. The CubeBOX Tower joins Tezmaksan’s expanding CubeBOX portfolio, which already includes advanced models such as CubeBOX Blues DR, RT and Space Cabinet.

Mr Aydogdu concluded: “With its innovative design and intelligent control architecture, CubeBOX Tower demonstrates Tezmaksan’s commitment to delivering efficient, user-friendly and accessible automation for global manufacturing.”