Voortman

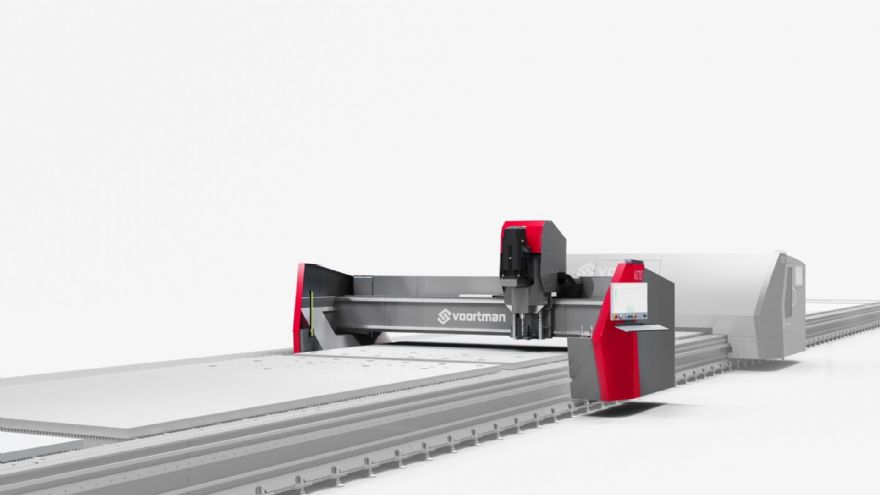

Voortman has introduced the V210, an extension to its V353 plate laser, designed to deliver complete plate processing in a single setup. The new configuration combines the speed and precision of fibre-laser cutting with the versatility of drilling, tapping and milling, offering a hybrid solution aimed at steel service centres and machinery fabricators seeking higher throughput, reduced handling and fully automated production-ready output.

The V353, a large‑format fibre laser known for high cutting speeds, accuracy and edge quality, is now complemented by the V210 plate processing unit. Operating as a separate gantry on the same machine bed, the V210 enables machining processes to run alongside laser cutting without compromising cut quality. Stef Rohaan, product manager at Voortman said: “Operating as a separate gantry, the V210 runs simultaneously on the same bed without compromising laser quality, expanding the V353’s flexibility offering an integrated plate processing solution.”

The V210 is engineered to handle plates up to 75mm thick and can drill holes up to 50mm with threading capabilities to M30. The unit carries 28 tools, with quick-change capability provided by an eight‑position gantry‑mounted changer located close to the drilling head, supported by an optional 20‑position stationary changer for fully automated exchange. High‑stability drill clamps minimise vibration, allowing the high‑torque spindle to deliver consistent power, extended tool life and improved hole quality. The process is fully automated aside from plate loading and removal of finished parts.

He added: “This setup enables both high-mix, low-volume and batch production in one workflow. One can seamlessly switch between cutting and machining without moving the plate. The result — faster throughput, less crane time, and reduced work-in-progress.”

While most operations are completed by the laser, the V210 adds high-quality drilled holes, tapped threads, countersinks, and milled pockets to deliver production ready parts. Mr Rohaan concluded: “This allows Steel Service Centers and machinery fabricators to operate as a true ‘one stop shop’.”