Industrial automation specialist

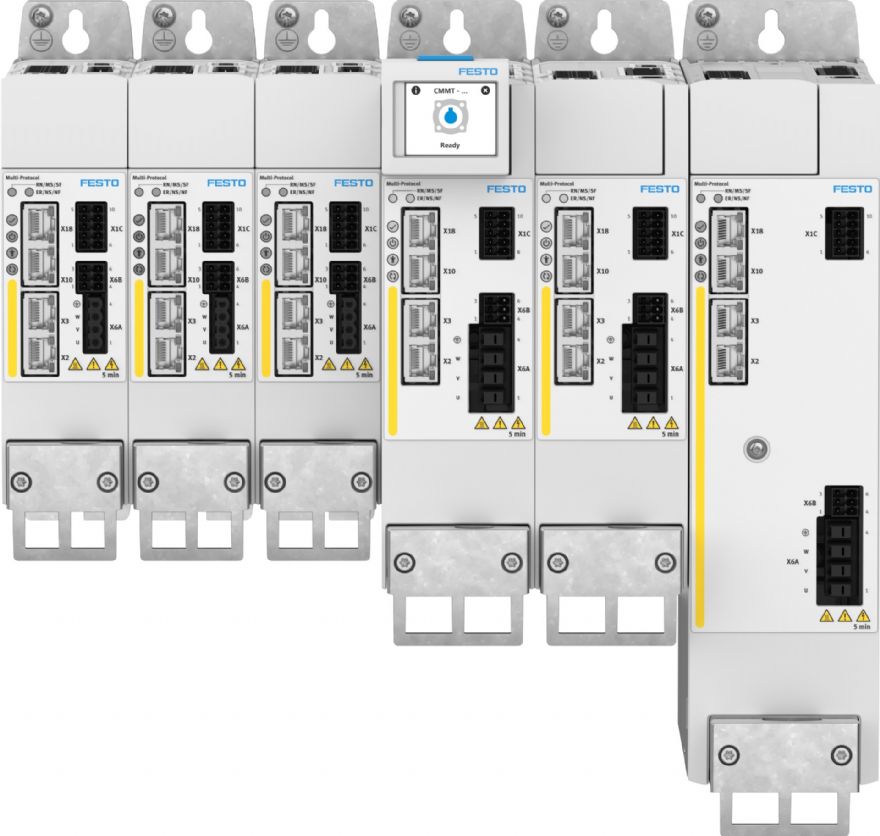

Festo has expanded its drive technology portfolio with the launch of the CMMT‑AS‑MP‑S3 servo drive, a compact unit designed to simplify the integration of high‑level functional safety in automated machinery. The new model builds on the established CMMT‑AS range, combining motion control and extended safety features in a single package aimed at demanding applications in assembly and handling systems, packaging machinery and electronics production.

Ben Lloyd, product manager for electric automation at Festo, said: “The CMMT-AS-S3 delivers the power and precision Festo customers expect, but with extended and integrated safety features. We have packaged everything into a compact servo drive that requires no additional wiring or modules, delivering space and cost savings and reducing complexity while meeting the highest standards of functional safety.”

The drive is suitable for power ratings between 300W and 12kW and enables users to achieve up to PLe, SIL3 and Category 3 and 4 safety levels. Integrated functions include Safe Torque Off (STO), Safe Brake Control (SBC), Safe Stop 1 and 2 (SS1 and SS2), Safe Operating Stop (SOS), Safe Maximum Speed (SMS) and Safely Limited Speed (SLS). The system can be used across Festo’s full range of mechanical axes for both linear and rotary motion.

The CMMT‑AS‑S3 also supports multi‑protocol Ethernet connectivity, ensuring compatibility with EtherCAT, EtherNet/IP, PROFINET and ModbusTCP. This allows software engineers to integrate the drive easily into Festo’s wider pneumatic and electric automation ecosystem. Safety parameters can be set without software, but using the Festo Automation Suite (FAS) provides guided commissioning with a graphical interface covering safety configuration, validation, programming, diagnostics and firmware updates. The software includes realistic preset values, step‑by‑step safety validation and tools for I/O and fieldbus setup, as well as automatic generation of validation reports.

With the introduction of the CMMT‑AS‑S3, Festo aims to streamline safety integration while reducing control cabinet space and simplifying installation for machine builders seeking robust functional safety in compact form.