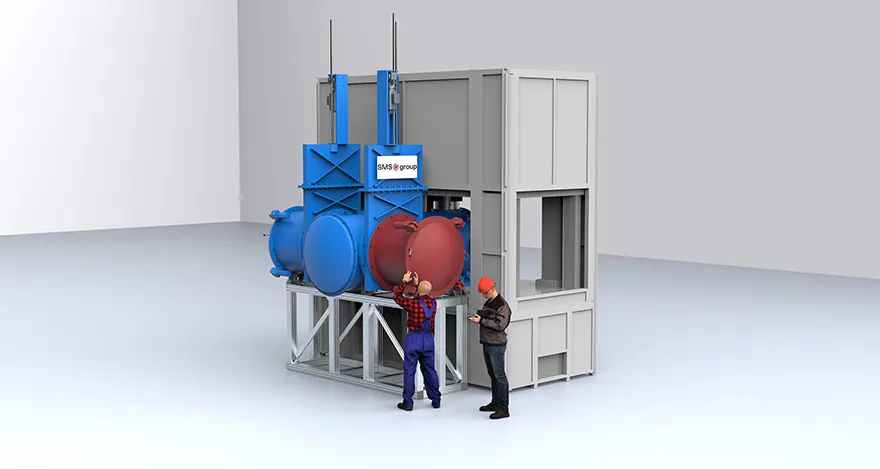

3-D visualisation of the isothermal forging module integrated in the pressSMS group

3-D visualisation of the isothermal forging module integrated in the pressSMS group is to supply a ‘state of the art’ isothermal forging module to the

Institute of Forming Technology and Machines (IFUM) at

www.uni-hannover.de/en Leibniz University in Hanover. The flexible and mobile vacuum module will be integrated into the existing synchronous screw press and implemented as part of the ‘High-performance materials of the future – HoWZu’ research project, funded by the European Union’s EFRE infrastructure programme and the state of Lower Saxony.

The project aims to develop new, scalable methods for processing innovative high-performance materials that cannot be formed under conventional conditions. The mobile system is designed for flexible integration into the existing synchronous screw press, which has a maximum press force of 6,000 kilonewtons, and can be dismantled if required. The isothermal forging module is scheduled to go into operation at the Hannover site by the end of 2026.

Julius Peddinghaus, bulk metal forming team leader at IFUM, said: “We chose SMS group as our supplier and partner. We were impressed by its proven expertise in vacuum technologies for secondary metallurgy and profound understanding of metallurgy. With our new isothermal forging module, we are driving the evolution of novel superalloys and setting new standards in isothermal forming.”

Isothermal forging is a highly specialised process used for reactive high-temperature materials such as titanium and nickel-based alloys. The process combines constant temperature, vacuum or inert gas conditions, and controlled material behaviour during hot forming. This prevents unwanted chemical reactions and ensures a uniform microstructure.

Inside the module, a batch of up to 10 powder-pre-pressed blanks is processed fully automatically. The blanks, made of superalloys such as titanium and nickel-based alloys, are placed in the loading chamber. After closing, the air is pumped out to a pressure of approximately 0.012mbar, creating a vacuum to prevent reactions with oxygen.

The workpiece and pressing tool are then heated to around 1,100°C. Maintaining identical temperatures for both tool and workpiece prevents undesired changes in the microstructure during forming. A robot operating in a vacuum removes the heated workpiece from the furnace and places it precisely into the die. The deformation process occurs under isothermal conditions at a very slow rate. After forming, the robot transfers the component to the extraction chamber, which is opened only after all parts in the batch have been processed.

Axel Rossbach, technology expert at SMS group, concluded: “Our close cooperation with IFUM in research and teaching has fostered a trusting partnership. We are proud that our new development has impressed all concerned and look forward to continuing this successful collaboration.”

With this investment, IFUM will gain a powerful research tool that will significantly advance the development of new materials for demanding applications in aerospace, medical technology, and industry.