TDM Systems

TDM Systems has introduced

TDM Release 2026, a major update designed to elevate digital tool and data management across the shopfloor. The new release expands automation, strengthens connectivity and brings mobile capability further into day‑to‑day manufacturing workflows, allowing users to streamline processes and increase overall equipment effectiveness.

A core feature of

TDM Release 2026 is the fully automatic data transfer to machine tools via a standardised connection. Data is sent seamlessly and without interruption, removing the need for manual intervention and ensuring that critical tool information reaches the machine in real time. The new mobile functions extend this further, providing rapid access to tool data, NC programs and key tasks directly at the machine or tool crib. Tools can be booked to cost centres using barcodes, and NC programs can be retrieved on the move, reducing waiting times and supporting a more agile workflow.

The centrepiece of the release is the ‘TDM Machine Data Connector’, a standardised interface that advances automation on the shopfloor. While TDM has supported dedicated machine connections in the past, this new interface is designed to work with most modern control systems. It is already compatible with Heidenhain controls and will support Siemens and Fanuc systems from mid‑2026. By enabling complete bidirectional data flow—from tool master data to wear values—independent of the controller in use, the system delivers full transparency and enables predictive planning, resulting in higher productivity and fewer errors.

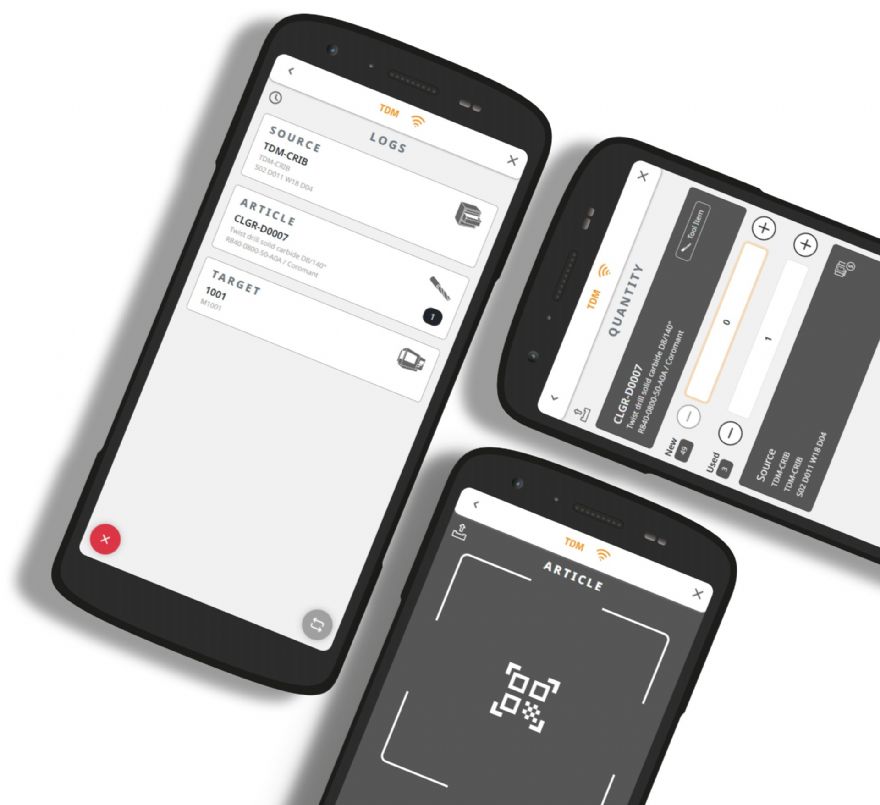

Mobile tool handling also receives a significant upgrade with the enhanced TDM ScanEasy app. The app now supports all tool crib processes, inventory tasks and quantity bookings, helping users carry out tool management functions faster and with fewer steps. Alongside displaying detailed item information, the app allows mobile tool booking directly at the workstation or machine. A new dynamic search feature provides relevant item suggestions after only a few characters are entered, making it quicker to locate tools and components.

Synchronising inventoriesConnectivity remains one of TDM’s strongest characteristics, and Release 2026 expands this further with integration to the CRIBWISE manufacturing inventory management platform from

Sandvik. The systems now exchange component data, synchronise inventories and allow stock movements to be booked in either platform. For users operating TDM alongside CRIBWISE, this integration supports automated ordering workflows and a transparent, up‑to‑date warehouse structure for consumable tooling.

TDM’s Integrated NC Program Manager has also been strengthened with TDM NC Web Transfer, a browser-based tool that allows approved NC programs to be provided to machine-related directories or returned after on‑machine optimisation. This improves program handling, saves time and increases visibility across the machining environment.

Further improvements have been made to the ‘TDM Gauge’ and ‘Calibration Management Module’. Because calibration and testing are often performed by external providers, the new release enables users to import measurement and calibration data from external systems, ensuring that records are kept fully up to date and that test equipment management remains efficient and transparent.

Release 2026 also introduces broader data maintenance tools to streamline bulk processing of components and complete tools. These include improved mass data handling, simple conversion between metric and imperial units, automatic collision data generation for large datasets, selective deletion of graphics or data fields, more accurate graphic measurement and easier assembly of complex tool structures.

Matthias Gröger, head of product TDM at TDM Systems said: “With the

TDM Release 2026, we are taking the next step towards consistent digital tool management across the shopfloor. Our focus is not only to manage tool data digitally, but also to ensure the entire system is even better connected. For our clients this means higher productivity, less downtime and machines that operate to their full potential.”