SmartScope M130 introduces next-gen enhancements in image accuracy, optics, and throughput for manufacturers producing large, heavy partsOptical Gaging Products

SmartScope M130 introduces next-gen enhancements in image accuracy, optics, and throughput for manufacturers producing large, heavy partsOptical Gaging Products (OGP), a world-leading manufacturer of optical and precision multi-sensor metrology systems for industrial quality control, has launched its latest addition to the next evolution of SmartScope 3D Multisensor Metrology systems — the SmartScope M130.

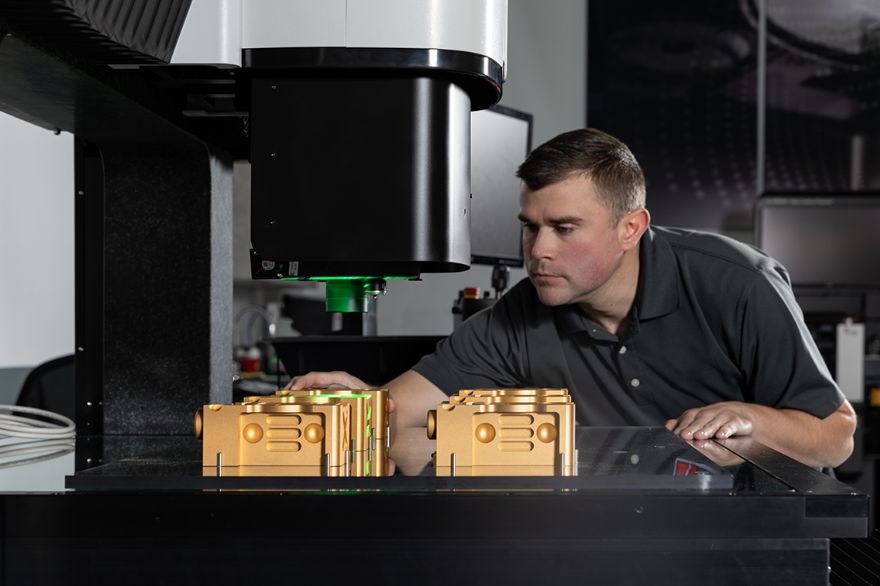

For leading manufacturers crafting large, heavy parts, SmartScope M130 ushers in the next generation of enhancements in image accuracy, optics, and throughput in a new large format 3D multi-sensor video measurement platform.

Tim Fantauzzo, vice president of North American Sales, said: “The SmartScope M-Series family has quickly been adopted by manufacturers seeking unrivalled confidence in repeatability and reliability. Larger parts obviously can contain many more detailed features. The M130 optical system is truly telecentric with no distortion, so manufacturers making large, heavy parts can achieve more accurate measurements particularly at low magnification with far more part features in the field of view.”

At the core of SmartScope M130 is the patented IntelliCentric-M Optical System, featuring fixed optics with a 20 mega-pixel camera and proprietary Virtual Zoom technology. Built from the ground up at OGP’s headquarters in Rochester, New York, the streamlined IntelliCentric-M optics employ a variety of exclusive technologies allowing for instant magnification changes throughout the same zoom range as a traditional mechanical zoom system, resulting in faster runtime while requiring far less downtime for maintenance.

Ideal choice for measuring larger partsSmartScope M130 is the ideal choice for manufacturers making large parts that require advanced throughput solutions. The IntelliCentric-M optical system combined with advanced sensors, illumination, and accessories, achieves class-leading optical measurement speeds.

With robust standard X, Y and Z-axis travels of 790 x 815 x 200mm (optional 300 or 400mm Z-axis), and payload capacity of 75kg, SmartScope M130 offers next-generation M-Series benefits to manufacturers producing large parts. A new innovative base design results in a lower stage height, allowing users to load and unload heavy parts or oversized fixtures with ease.

OGP President Steve Flynn, said: “Since 1992, OGP SmartScope systems have helped thousands of manufacturers around the world achieve confidence in their quality programmes. With SmartScope M130, we have applied the latest evolutions in optics and software in a larger format, creating the next generation of leading metrology solutions for manufacturers making large and heavy parts.

“M-Series systems take full advantage of the advanced edge detection algorithms, parallel processing, and routine optimisation found in ZONE3 Metrology Software to deliver advanced throughput and enhanced accuracy for manufacturers in any industry. We are excited for our customers producing large parts that have realised these benefits on their compact format M-Series systems, as well as new OGP users alike, to discover how SmartScope M130 will vastly improve their inspection operations.”

For more information about OGP SmartScope M130, the full family of SmartScope M-Series Metrology Systems, and to schedule a demonstration with your local OGP authorised representative, visit the website

here.