Responding to the increasing use of hybrid manufacturing, the latest release of Edgecam — 2019 R1 (

www.edgecam.com) — features a new Additive Machining module that supports the Direct Energy deposition method.

After being formed, parts are machined using Edgecam’s milling cycles — including rotary and five-axis simultaneous machining — to create the final component.

Edgecam brand manager John Buehler says the new Additive Lace cycle is designed to construct geometry on a layer-by-layer basis, depositing a continuous molten bead of material that adheres to the parent material.

“Using the same intuitive dialog interface as all other Edgecam cycles, Additive Lace not only offers the ability to work with various CAD entities but also allows the user to determine numerous control types, such as lace angle, amount of finish passes, and undercut mode.”

In total, Edgecam 2019 R1 includes around 30 individual enhancements, including three performance-boosting changes that benefit both turning and milling operations.

For example, the regeneration time has been reduced by around 20% when editing the Move Angular/Index commands, and the Waveform machining algorithm has been enhanced to reduce the processing time.

Furthermore, due to improvements in the way Edgecam’s ‘machining engine’ generates data, the machining of large complex components is now considerably quicker.

Furthermore, a new parting-off cycle that allows the back edge to be deburred during the operation is available for turning customers, as is a new Up-Cutting function within the Finish Turning cycle.

This allows high-productivity finishing to be achieved in conjunction with Sandvik Coromant’s CoroTurn Prime tools and inserts.

Meanwhile, the Stock Runout function within the Rough Turn cycle has been enhanced to give greater tool-path control when exiting the cut (the inclusion of Runout Angle and Runout Length means tool-paths can be trimmed to user-specific demands).

Furthermore, the Spindle Set-up function for multi-spindle lathes now includes main-spindle and sub-spindle C-angle positions, further guaranteeing no collisions during the ‘parts transfer’ command.

There have also been 13 new enhancements to Edgecam Inspect, including switching the “mathematical brain” behind the product to PCDMIS.

As a result, all Geometry Fit calculations, such as measurement deviations and GD&T values, now use a higher level of certified and approved algorithms.

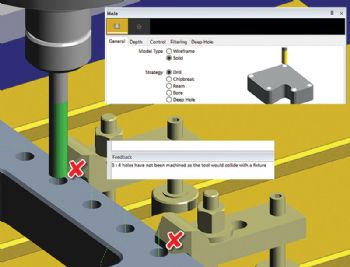

Improvements have also been made to: probing canned cycles; the Hole Cycle, which now has additional collision checking; and the Chamfering cycle, which now has a gouge-checking capability.

Edgecam 2019 R1 also supports the latest version of all CAD files.