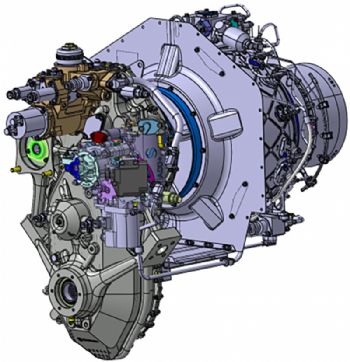

The result of a partnership between several Safran companies, the Add+ engine demonstrator will enable 3-D printed parts to be used in Group production engines.

Development started in early 2018, and assembly is now in progress; the demonstrator is scheduled to be ‘ground run’ next autumn.

Etienne Hesse, research and technology project manager (and Add+ programme co-ordinator) at Safran Helicopter Engines (

www.safran-group.com), said: “Add+ brings together 3-D printing expertise from across the Safran group.

"We started work on an existing engine model and redesigned almost 30% of its components using additive-manufacturing techniques, with a view to integrating them into serial production units. When we start ground runs, we will evaluate the behaviour of these new parts in operation.”

Based on an Arrius helicopter engine, Add+ will evaluate major components made using Selective Laser Melting techniques.

Meanwhile, Safran Aero Boosters has been awarded certification by the EASA1 and FAA2 airworthiness authorities for LEAP aero-engine lubrication units equipped with a 3-D metal printed casing — a first for an engine component of such complexity.

Safran Aero Boosters (a partner of Safran Aircraft Engines on the LEAP engine) designs, develops and manufactures low-pressure compressors, front bearing supports and engine oil equipment (lubrication units and tanks).

As an alternative to the casing previously manufactured in the foundry, Safran Aero Boosters’ research and technology teams have developed a casing with a design that is optimised for additive manufacturing.

Launched at the end of 2015, the study of this new process on two prototype lubrication units led in less than a year and a half to a new design adapted to the constraints of 3-D printing and the production of 14 parts ready to undergo certification and ‘technological maturation tests.’

A ‘printed’ lubrication unit has been installed on a LEAP-1A-series engine that powers the Airbus A320neo.