London-based AM specialist

3D People is calling on manufacturers to rethink how they evaluate 3-D printing, warning that an obsession with price per part risks obscuring the true value it brings to modern production. In its latest insight piece,

The Real Cost of 3D Printing: Beyond Price per Part, co-founders Sasha Bruml and Felix Manley argue that while unit price comparisons make sense for traditional processes such as injection moulding, they fail to capture the transformative economics and agility of AM.

Mr Manley said: “Additive manufacturing (AM) is not just a different way to make parts, it is a completely different production philosophy. When companies focus purely on price per part, they miss the bigger picture — design freedom, shorter lead times, reduced inventory, and a more responsive supply chain. These are real commercial advantages that don’t show up on a spreadsheet.”

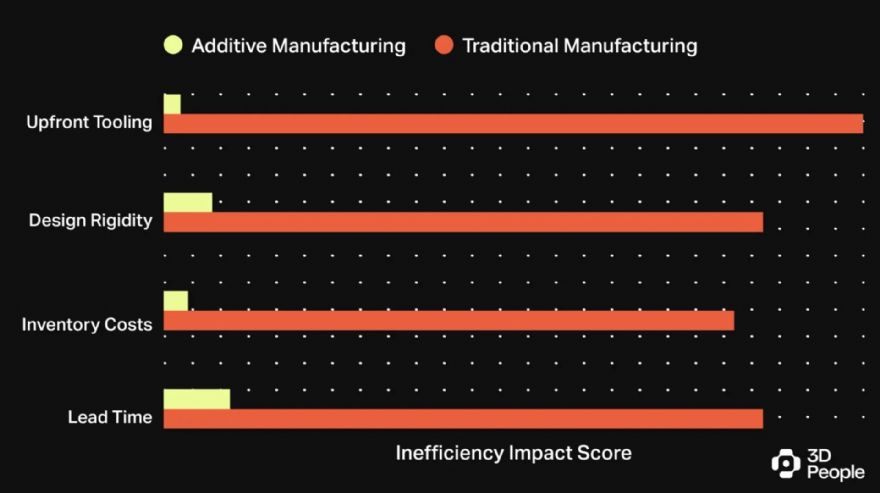

Unlike conventional manufacturing, (AM) processes require no costly tooling, enable rapid design iteration, and allow on-demand production. This flexibility eliminates stockholding and warehousing costs while giving engineers the freedom to optimise components for performance rather than manufacturability.

Long-term valueMr Bruml added: “The smartest companies are looking beyond unit cost and focusing on total cost of ownership. “When you factor in savings from lighter designs, reduced assembly complexity, and fewer warranty issues, AM often delivers better long-term value, even when the price per part appears higher.”

3D People highlights that hidden savings in logistics, quality assurance, and post-processing make additive manufacturing an increasingly strategic choice, particularly for low-to-mid volume production and products with shorter life cycles. By guiding customers through the entire value chain—from design optimisation to surface finishing and part validation — the company positions itself as a strategic manufacturing partner rather than a simple supplier.

Mr Manley said: “We don’t just quote parts, we collaborate. Our mission is to help engineers and procurement teams see additive manufacturing as a full manufacturing solution, not just a quick fix.”

As industries across the UK and Europe embrace on-demand digital manufacturing, 3D People’s message is clear: the future of manufacturing isn’t defined by price per part, it is defined by performance per part.