The Telford-based ‘digital’ manufacturer Protolabs (

www.protolabs.co.uk) has launched polypropylene 3-D printing in Europe, having invested significantly in developing this material for use in selective laser sintering.

This gives design engineers the opportunity to develop and test prototypes rapidly.

It also allows complex designs to be produced using 3-D printing — designs that previously could not be made using this material.

Andrea Landoni, 3-D printing product manager for Protolabs, said: “Polypropylene is widely used for a number of applications, but until recently you could only use 3-D printed polypropylene-like materials that mimicked this plastic but they did not have all its properties — and were not as durable.

"Now that we can produce prototypes in polypropylene, design engineers can develop and test them using the same material that they will be manufactured from — re-iterating and re-testing designs until they have the perfect solution before committing to tooling.”

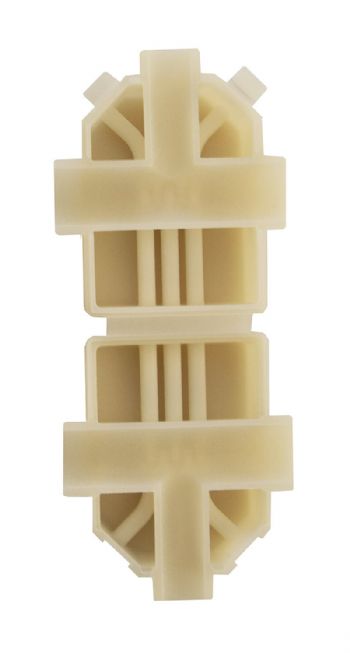

3-D printing polypropylene opens up a host of designs with complex geometries that were previously impossible.

These include honeycomb structures to reduce weight, and ‘organic’ shapes such as internal channels.

Ms Landoni added: “Before, if you wanted to use polypropylene you were limited in what you could design by the manufacturing technology available.

Now, the only limitation is your imagination.

"There are many times, however, when the best solution for a manufacturer may be to produce polypropylene parts using

injection moulding or CNC machining.

"We can give customers unbiased advice on which is best to use, because we now offer all three manufacturing technologies.”