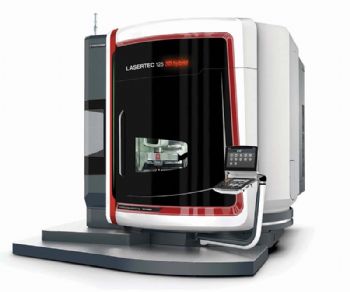

A new five-axis machining centre with integrated laser deposition welding capability for the complete production of complex components in one hit has been introduced by Coventry-based DMG Mori UK Ltd (

www.dmgmori.com).

The LaserTec 125 3D hybrid is intended for the manufacture, maintenance and repair of workpieces up to 1,250mm in diameter x 745mm high and weighing up to 2,000kg.

The company launched this technology in 2013 with a smaller model, the LaserTec 65 3D hybrid. The machine range has gradually been extended, first with the LaserTec 4300 3D hybrid (combining additive manufacturing using a powder nozzle and turn-mill machining in one work area) and then with powder-bed machines in the LaserTec SLM series.

Based on the machine tool builder’s MonoBlock platform, the LaserTec 125 3D hybrid offers ‘high dynamics, rapid build rates and excellent repeatability’; and with automatic change-over between laser deposition welding and simultaneous five-axis milling in a single set-up, processing times are cut by up to 80%.

Such savings are helped by eliminating the need for heat treatment as a separate process step, because the machine can deposit material with a hardness up to 63HRC.

A further ‘selling point’ of laser deposition welding is the ability to change between two materials quickly under CNC; for example, hard surfacing to reduce wear can be carried out in one area, and corrosion-resistant welding for

environmental protection can be carried out in another.

The cooling characteristics of a part can also be enhanced; a die-casting mould can have a bronze core that dissipates heat effectively and an outer skin of tool steel — and these machines can be used for a variety of repair and re-coating applications.

As with its sister models, the LaserTec 125 3D hybrid can be integrated into a CAD/CAM process chain. High-performance hybrid CAM software for powder nozzle technology (developed especially for DMG Mori by Siemens NX) enables end-to-end programming of repairs, with users able to change seamlessly between machining and laser deposition welding during programming.