Spindle Revolution (

www.cnc-spindle.repair) has begun the New Year with the opening of a new ‘state of the art’ spindle repair facility in Gloucestershire.

Building on its reputation for high-quality repairs that were previously carried out in Germany, the company will now offer customers a more-efficient and cost-competitive solution by moving all repairs to the new facility near Lydney.

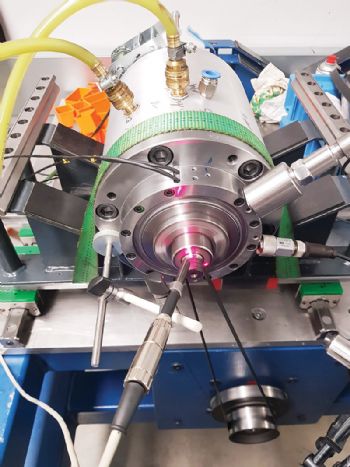

Using purpose-built testing machinery, Spindle Revolution can test and diagnose all spindles and motors up to 180,000rev/min — regardless of taper type, lubrication method or encoder designation.

The new test centre is one of the most advanced in Europe, enabling a huge amount of data to be gathered on all parameters of the spindle.

With this information, Spindle Revolution can ensure that every spindle repair is carried out to the highest level, before the spindle is subjected to prolonged testing at maximum revs to ensure trouble-free installation.

Managing director Julian Kear said: “Spindle Revolution has invested in ultra-modern equipment for the new test facility. We will provide the customer with a level of detail and expertise previously unseen in the world of spindle repairs.

"Our reports give an open and honest appraisal of the condition of the spindle or motor as we receive it.

“Everything is measured and reported, with nothing hidden; this allows our customers to make an informed decision on the level of repair they need.

"Due to the amount of data we gather on each spindle, we are often able to offer an optimised repair solution.

“This may include uprated bearings for customers who run spindles at high speed, or stronger bearings for customers who require lower revs with increased resilience to wear.

“For added peace of mind, all repairs are supported by our standard 12-month warranty.”