GE Additive has launched the Arcam EBM Spectra L to meet the demand for higher productivity and larger build volumes, especially from the aerospace industry; it also offers an integrated system architecture, new machine health analytics and automation features.

This latest addition to the Spectra family will be manufactured at the GE Additive Arcam EBM facility in Gothenburg, Sweden; it is available for order now, with delivery at the end of Q1 2020.

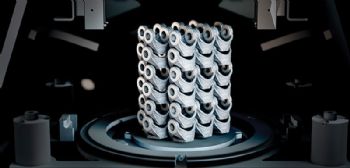

Spectra L, which supports grade 5 Ti6Al4V and grade 23 Ti6Al4V, accommodates large titanium applications that cannot be achieved with laser. Support for pure copper is planned for 2020.

GE Additive (

www.ge.com/additive) says that the gains in build volume (350mm in diameter x 430mm high) and build speed offered by the Spectra L can reduce the cost per part by 10%.

This machine features a 4.5kW beam power, which increases build speed by 20% compared to the Arcam EBM Q20plus, allowing it to complete a full-height build 4.5hr quicker.

The Spectra L also provides a more consistent and accurate beam with improved auto beam calibration, resulting in more consistent material properties for both thin and bulky geometries.

It is also compatible with the Arcam EBM PRS 30 — a new automated powder retrieval system for ‘serial additive-production environments’.

Advanced data analytics are incorporated into the Spectra L.

By combining data selected from sensors in the machine with ‘intelligent algorithms’, process and machine health analysis can be carried out, as can reporting, root cause analysis and recommendations for corrective actions.