3D Systems is ‘transforming’ customers’ digital design and manufacturing environments and putting software at the core of its strategy with the introduction of its 3DXpert for SolidWorks 15 (

www.3dsystems.com).

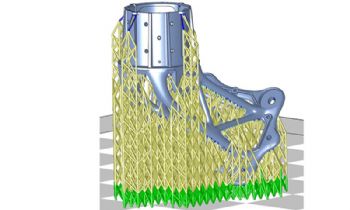

This is configured to allow users of SolidWorks software to “easily prepare and optimise” their designs for additive manufacturing, design complex structures and accelerate the product design life-cycle with better automation and seamless bi-directional data exchange from and to SolidWorks.

3D Systems said: “The growth of additive manufacturing is contingent on optimising digital workflows, and that begins with re-imagining how software supports the process and corrects the core issues that pose significant challenges for designers.

"Until now, the design tool-set available has been oriented for traditional manufacturing techniques, and this has created barriers to digital manufacturing workflow optimisation.

"In addition, designers have faced demand for lighter-weight parts — and parts with complex geometries. 3D Systems’ latest software solution addresses these challenges and unlocks new possibilities.”

3DXpert for SolidWorks 15 enables users to: shorten the design cycle with enhanced bi-directional data transfer; optimise design structure with an enhanced lattice development suite; easily achieve successful prints with automated tools and workflows; and benefit from enhanced build simulation capabilities that give designers clear and immediate feedback on their design decisions.