SBI GmbH, an Austrian manufacturer of high-tech additive-manufacturing systems using plasma-arc additive-manufacturing (PAAM) technology, offers its M3DP machine for AM applications in a variety of industries — such as aerospace, oil and gas, marine and shipbuilding, tool-making — and in general service and maintenance applications.

The company recently signed a partnership agreement with the French company Multistation that allows the latter to sell the M3DP machine in France.

CEO of SBI Martin Peruzzi said: “We are very happy that we can introduce our new M3DP product range to the French market, particularly as this machine can be used for aerospace additive-manufacturing applications. The experience of Multistation in the field of AM will support the introduction of our product range into French industry.”

CEO of Multistation Yannick Loisance said: “With the M3DP line from SBI, we complete our offer of metal AM processes with a very powerful process that is complementary to our various offerings in laser or electron beam bed melting, supersonic or binder jetting and DED — directed energy deposition. Having SBI as our partner, we can now offer a complete portfolio of solutions.”

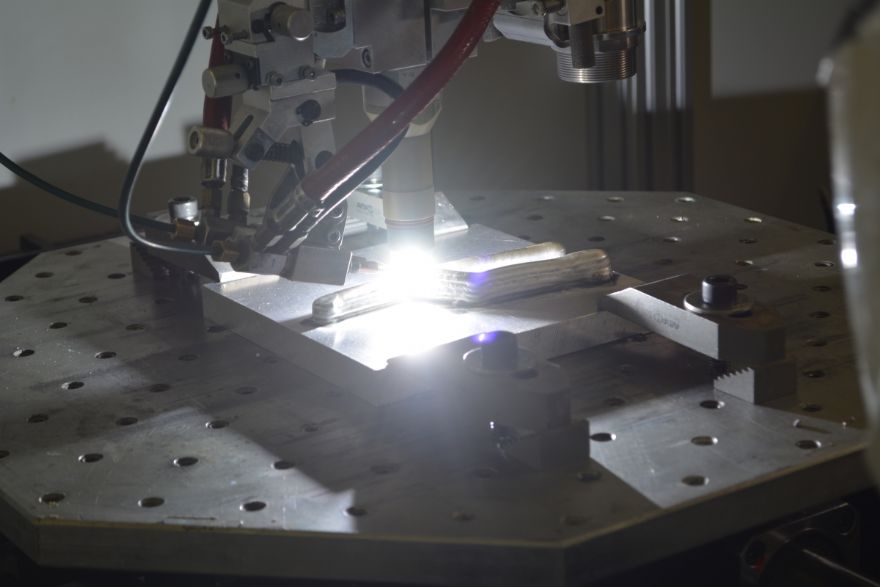

PAAM is a high-performance AM process in terms of deposition rate, build volume and ‘economic issues’. A plasma torch creates a weld pool; a local deposition is then achieved by adding metallic feedstock (wire and/or powder).

By moving the plasma torch and the feedstock along a programmed path, a layer is printed. The superposition of multiple layers creates a three-dimensional object. PAAM is referred to as a “near net shape” process, because the printed object has to be machined to reach its final shape.