PCL, a Sheffield-based pneumatics company, is bringing electronic testing and development in-house after substantial investments in its equipment and team.

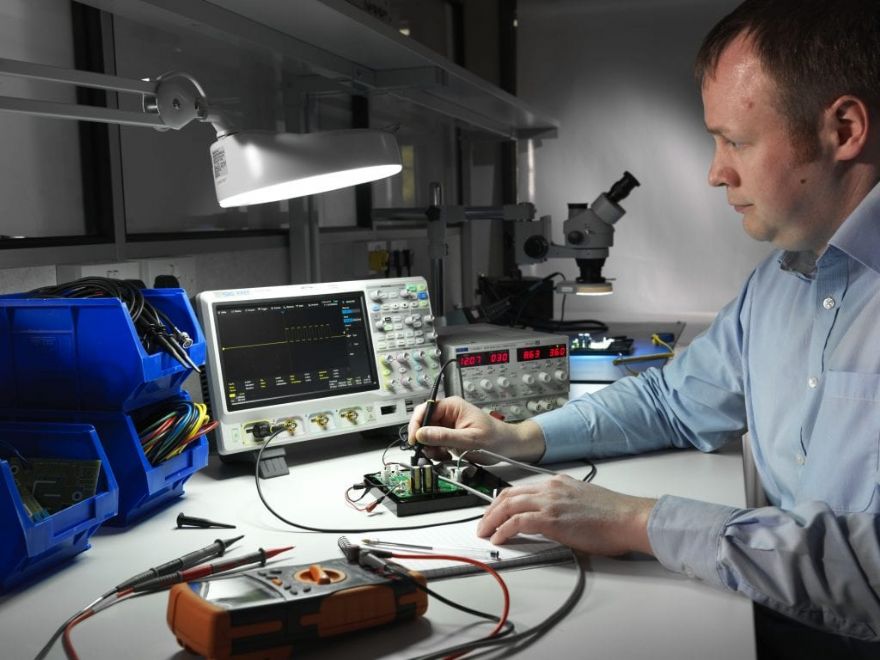

Led by senior electronics development engineer Michael Crookes, the introduction of this new facility will enable PCL to test and develop electronic products in-house.

The dedicated laboratory houses general electronics test and measurement equipment, including an oscilloscope and logic analyser, a waveform generator and a precision digital multi-meter — plus soldering equipment, a zoom microscope and a hot-air rework station.

PCL says this latest commitment to developing the company’s capabilities through ‘cutting-edge’ equipment and recruiting expert personnel confirms its position as a world leader in the manufacture and supply of compressed-air products. The company’s first pressure gauge was designed and manufactured in 1938.

Mr Crookes, who has a background in laser manufacturing and electrochemical microscopes, says that PCL has a huge opportunity to take its existing product platform to another level and explore other compressed-air markets, allowing him to take a hands-on role in product enhancement.

He said: “PCL has an exceptionally skilled workforce, who are experienced in developing ground-breaking products. Bringing electronic testing and development in-house gives us the ability to advance existing product ranges and create new digital ones in response to market trends and client needs.

“It also enables us to work on projects involving minor changes, such as tailoring existing products to meet specific customer requirements through bespoke configuration — for example, a particular type of payment system for a forecourt inflator.”