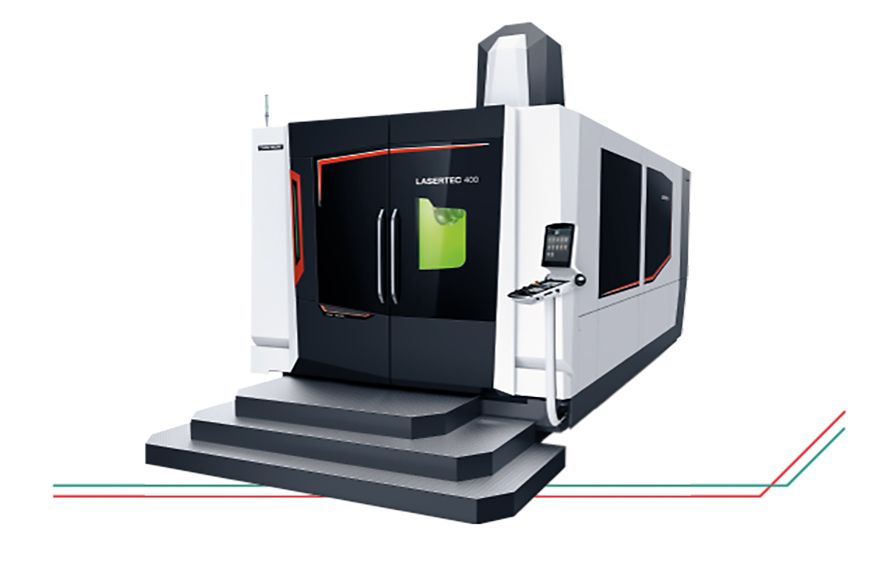

A new gantry-type five-axis CNC machine for rapidly laser texturing the 3-D free-form surfaces of moulds and tools weighing up to 20 tonnes — and with maximum dimensions of 3,350 x 1,350 x 1,000mm — is now available from Coventry-based

www.dmgmori.com DMG Mori UK Ltd.

The LaserTEC 400 Shape is the largest model in a range of four laser ablation machines, the others being designated 45, 75 and 125. Another machine is planned with a 2,000mm X-axis — the LaserTEC 200 Shape.

The company says it is becoming increasingly important in many industries — especially automotive and aerospace — to impart geometrically defined surface structures to plastic injection moulds and press tools in order to improve the aesthetics and functional properties of the components they produce.

“The machining of textures is more environment-friendly than conventional etching, and it offers considerable freedom of design, while at the same time ensuring a high level of repeatability. It can also create filigree cavities without the need to manufacture electrodes.”

The LaserTEC 400 Shape (details and a video can be found at the Web site —

www.uk.dmgmori.com/products/machines/lasertec/lasertec-shape/lasertec-400-shape — is equipped with a newly developed narrow and compact ‘additive manufacturing’ laser head designed by DMG Mori.

It offers ‘excellent accessibility’ to a component — even one with deep and narrow features — eliminating the need for long focal lengths that would slow the ablation process.

Central to the machine’s operation are a 100W fibre laser (with a switchable pulse length and frequencies up to 1kHz) and 3-D processing optics (with an F-Theta scanning lens).

The two degrees of movement of the head are ±200deg rotation and a swivel range of -100 to +135deg (enabling under-cuts to be processed). The standard servo-controlled lens-focusing system (it travels at up to 5m/sec in the X , Y and Z axes) is key to increasing productivity, while ensuring the required accuracy.

Furthermore, the thermo-symmetrical gantry incorporates extensive cooling to ensure high-precision laser structuring; it also allows loading and unloading from above (by crane) to reduce set-up and handling times.

The work envelope is 4,000 x 2,000 x 1,200mm, the rapid-traverse rate is 50m/min, and there is linear-scale positional feedback in all three axes.

Control is by a Siemens 840 D solutionline; when combined with DMG Mori’s application-specific LaserSoft software and proprietary CELOS graphical user interface, this allows the machine to be ‘integrated optimally into a manufacturer’s organisation’.