Sheffield-based

Bowers Group has created a series of videos covering new functions included in the latest version of Fusion software from Baty International Ltd.

Featuring a number of powerful new updates, the software now includes a range of technical and feature enhancements including lens error mapping, drag and drop program positioning, custom reporting options and off-line vision/touch-probe programming from CAD.

Geoff Jackson, Baty business and product development director, said: “We are delighted to be able to offer customers and distributors this new series of videos on the latest enhancements to the Fusion software. The videos explain and demonstrate exactly how the new features make our highly flexible multi-sensor vision systems more capable and easier to use than ever before.”

Several enhancements have been added to enable users to quickly drive the camera/probe to specific locations and/or features using simple mouse gestures.

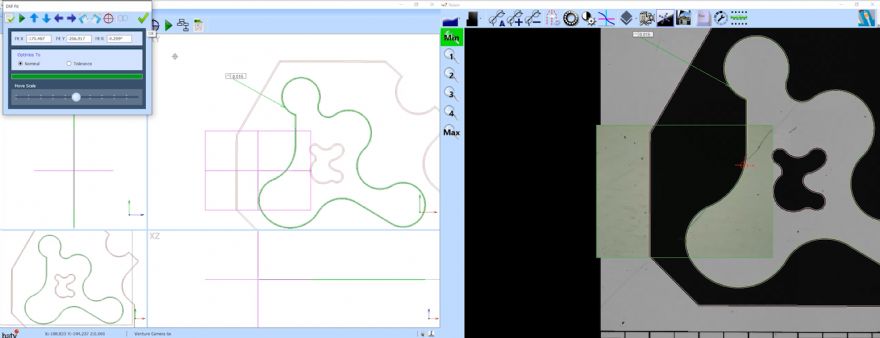

The new Mini-Map feature enables users to see which area of the part is being reviewed in detail, while maintaining a view of the entire part. Touch Probe moves are now a simple one-handed operation, thanks to an all-new touch screen joystick.

DXF CAD files can be overlaid over stitched images of the entire part for profile comparison. Dimensioned drawings of measured parts are easily generated with a combination of standard geometry as well as profile polylines for a clear visual representation of the scan.

Programming and positioning is now easier than ever, and many new dimensioning features are available to enhance reports, make them even easier to produce, and tailor the templates to customer needs.

The new Fusion software can be used on a variety of Baty’s highly flexible multi-sensor vision systems including the Baty Vumaster, Venture Touch, Venture Plus and the Venture XT.

The combination of contact and non-contact measurements in the same automated inspection, combined with ease of use and graphical reporting, make Baty’s Venture XT a cost-effective measurement solution for both production cells and QC labs alike.

The FT2-E readout can also be retrofitted to existing Profile projectors, transforming them into high accuracy, 2-D measuring machines with powerful reporting, without breaking the budget.

Fusion 4.16: An Introduction from Bowers Group on Vimeo.