Manufacturers using wire-cut EDM face a challenge when it comes to unmanned and lights-out operations — that of slug removal, which has invariably necessitated stopping the machine and manually removing slugs.

However, Coventry-based

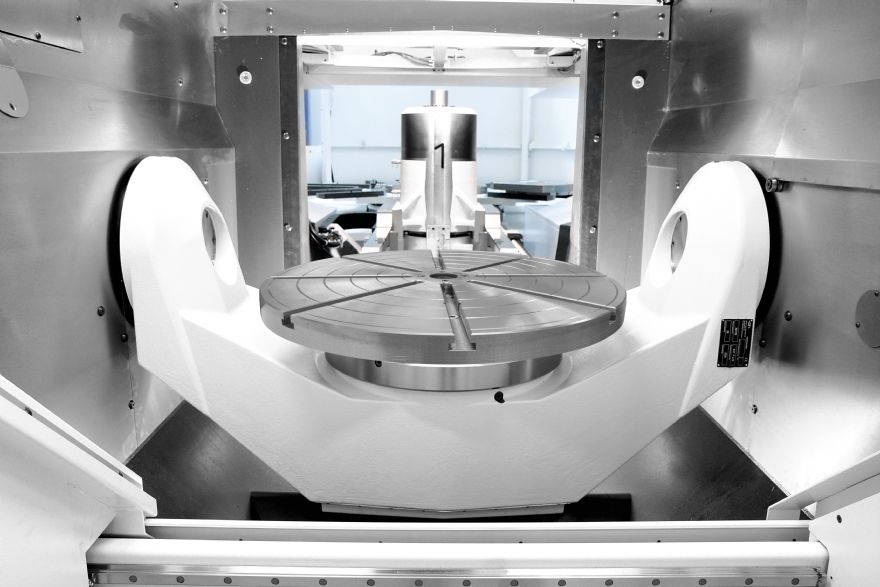

GF Machining Solutions Ltd is now offering a slug management/removal system for its latest wire cut machines.

Called Automatic Slug Management (ASM), this ensures that manufacturers can run their EDM machines in true lights-out style and benefit from reduced cycle times with no operator intervention.

Left to their own devices, slugs will fall onto the lower head of an EDM machine, possibly causing a crash that triggers alerts and stop the machine. To prevent this, CAM programs include ‘tabs’ that keep the slug connected to the workpiece during machining operations.

Once completed, operators remove the tabs and slugs, but such manual intervention prevents true unmanned operation. At best, manufacturers can achieve rough cutting of parts overnight, then wait until operators are available to remove the slugs before running trim and finishing passes; with ASM, parts can be rough and finish machined unmanned overnight.

The system is particularly well suited to die-stamping applications and other small cavity operations. The process begins with a complete roughing pass that leaves no welds or tabs but sees the machine’s lower head prevent the slug falling into the tank while a device retro-fitted to the upper head is lowered; this blows high-pressure air over the slug, which creates suction and allows the slug to be pulled from the part and deposited away from the machine.

Where slugs are too large/heavy to be removed by suction it is possible to remove them using a pocketing strategy that sees the EDM wire used like a milling cutter to machine the slug away.

However, it is more likely that a process known as ASW (Automatic Slug Welding) will be the process of choice. Although ASW does not enable true uninterrupted, lights-out operations, it does significantly reduce cycle times when using brass wire.

The slug-welding process uses G-code commands to control brass accumulation; it prevents top-to-bottom welds from occurring but does allow welds between the surface of the workpiece and the slug so that the slug can be easily knocked out of the workpiece.

The brass residue that remains does not interfere with or compromise skimming passes or other finishing operations. ASW is also available on GF Machining Solutions’ latest wire-cut EDM machines.