For over 30 years, Taunton-based

Pattern Forme Ltd has been an industry leader in the design and manufacture of thermoforming mould tools. The company specialises in producing tools for thin gauge work, mainly in the food industry and thick gauge work for applications including signage.

However, the key focus of the business is the food sector where its success has stemmed from a willingness to partner with customers. By offering its experience and being proactive it can take projects from initial concept to finished mould tool, often with lead times as short as two to three weeks.

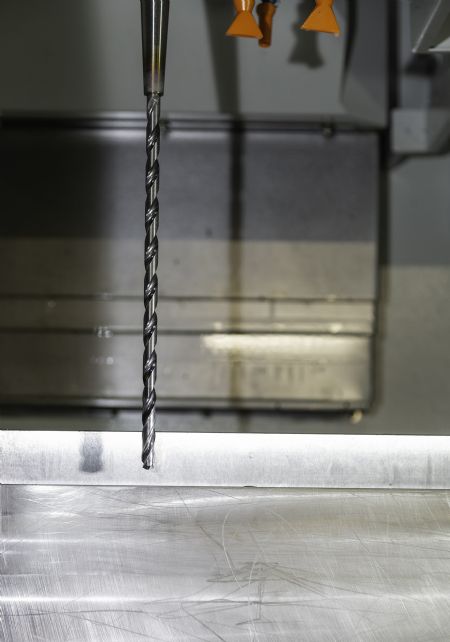

Latest machining technologiesThe food industry is fast-paced and constantly changing, therefore Pattern Forme has continually invested in the latest machining technologies. The recent trend has been for larger mould tools to increase productivity, which has led to a need to drill deeper holes.

Typically, these holes would range in size between 6 and 10mm diameter, with depths up to 1,000mm. The traditional solution would be to purchase a dedicated deep hole drilling machine or sub-contract the work.

The former would require a significant investment, whereas, the latter brings logistical problems and lack of control over production. XYZ Machine Tools was able to propose and deliver a quicker and more cost-effective solution.

Paul Wilkins, Pattern Forme managing director, said: “It was a chance conversation with

XYZ Machine Tools, who have supplied us with several machines, where I mentioned that we needed this extra capacity.

“They immediately suggested modifying one of its XYZ 1000 LR vertical machining centres to give the extra Z-axis capability we required.”

“The simple and cost-effective solution was to add a 1,050mm riser block to the machine, which would allow us to drill these holes from either end using the 500mm Z-axis of the machine.”

By reconfiguring the machine, XYZ Machine Tools was able to increase the minimum distance from spindle nose to table to 1,050mm and with the standard Z-axis stroke making the maximum distance 1,550mm which was more than enough to accommodate Pattern Forme’s components.

The order for the machine was placed in November 2019 and delivery to Pattern Forme took place in April 2020. Upon arrival, drill testing took place and the standard through-spindle coolant delivery of the machine at 20 bar proved sufficient and all that was required was the addition of an air filtration system supplied by LNS.

Now, using either gun-type drills or solid carbide twist drills Pattern Forme can further develop its deep hole drilling capability.

Excellent value

Mr wilkins continued: “This machine has been purchased purely for deep hole drilling and, considering the modifications, it is proving to be of excellent value with the capital cost alone around 80% less than a dedicated deep hole drilling machine.

“Efficiency will also improve as we can transfer work from what previously had been done on manual machines to a fully CNC controlled operation.

“A further advantage of this capability from the XYZ 1000 LR is the reduction in lead times, which is crucial if we are to maintain existing and win new business.”

XYZ Machine Tools is renowned for its extensive range of standard machine tools. However, this collaboration with Pattern Forme is a perfect example of how it listens to its customers and can quickly meet their specific requirements.

The solution presented by XYZ Machine Tools from a standard vertical machining centre is one that would have been difficult to find anywhere else and could have been prohibitively expensive.