Germany-based

Trumpf , a provider of manufacturing solutions in the fields of machine tools, laser technology, electronics and Industry 4.0, has launched the latest generation of its TruBend Cell 5000 automated bending cell which is programmed using TecZone Bend software.

It takes just seconds to create bending programs, making it more affordable than ever to process small batch sizes. The new machine is available in the UK from Luton-based subsidiary

Trumpf Ltd.

The TecZone Bend programming software that comes with Trumpf’s manual bending machines is now also included with the TruBend Cell 5000. It takes just seconds to program parts using the software and in most cases no manual intervention is necessary.

The software can even process multiple parts simultaneously where required and provides fully automated calculations of the optimum bending sequence, the optimum combination of tools and the path to be followed by the robot.

It also ensures collisions are avoided throughout the bending process and can break down assemblies in just one click to show the individual parts.

The programming system even generates suggestions on the best way to pick up the blanks and stack the finished parts, though users can manually adjust these suggested settings at any time.

Moreover, ‘smart’ automated functions free up programmers from some of the most tedious and repetitive tasks, giving an added boost to quality.

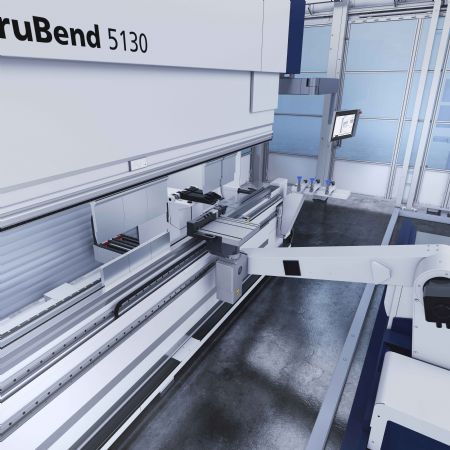

The new TruBend Cell 5000 is available with bending machines from the current TruBend 5000 series. It comes with a highly dynamic and precise drive that also offers extremely quiet and energy-efficient operation and consumes up to 50% less energy while increasing cell productivity.

A backgauge system ensures blanks are in exactly the right position in the machine during the bending process. An angle measuring system uses a laser to automatically check the bending angle. It works regardless of which tool is currently in use and makes any adjustments that may become necessary during operation.

The latest generation of the TruBend Cell 5000 is also equipped with numerous automation components. One example is the BendMaster, which handles bending operations. Trumpf developed this robot specifically for automated bending. and it is available with a maximum carrying capacity of 150kg or 60kg.

The BendMaster can be automatically provided with various grippers that allow it to convey blanks of up to 4m in length from a stack to the machine and the robot uses a newly developed digital sensor to automatically identify parts, enabling it to pick up each sheet in the appropriate way.

It uses either grippers or vacuum suction cups to pick up blanks depending on their size. The system also includes a double sheet detection feature that ensures only one sheet is removed from the stack at a time.

If the bending cell is connected to a storage system, the BendMaster retrieves the raw material directly from the storage cart. Finished parts can be sorted into boxes or placed on pallets and conveyor belts.