Identifying a business opportunity is one thing but making it a success is another. When the founder of China-based Wuxi Fortune Technology Co., Ltd decided to pursue manufacturing certification with one of the world’s largest automotive technology companies, he chose

Tornos as his partner for turning machines and the respective application and process support.

Established in 2002 with just one horizontal machining centre and a few vertical machining centres, Wuxi Fortune now has 350 employees that includes 38 process engineers and 35 quality engineers. The company’s two production sites, both in the Wuxi New District industrial centre 120km west of Shanghai boasts production space totalling more than 35,000m

2.

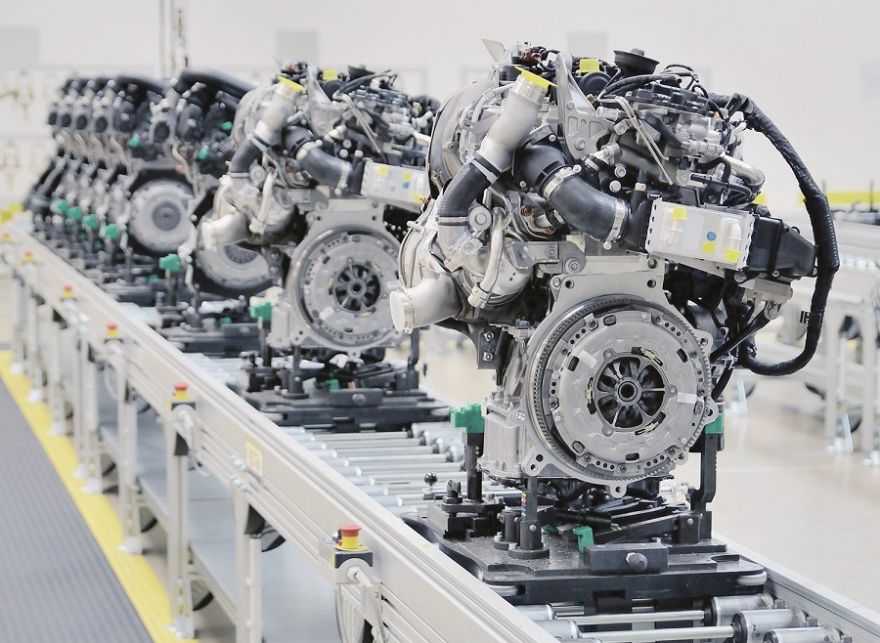

It is only natural that managing director Jian Wang set his sights on securing a place among Tier Two suppliers to China’s automotive industry as the country has the world’s largest automotive market producing 27.81 million cars in 2018.

At the same time, it is notoriously difficult; often taking up to three years for a new player to carve out a place in the Chinese automotive supply chain.

Mr Wang said: “The newly implemented National Emission Standard VI requires qualified long-term development partners, and there are quite a few in China in terms of technology, ideas and strategy.

“For large-scale suppliers with diverse business models, it is often difficult to meet the rapidly developing requirements. But Wuxi Fortune has automotive industry experience in the production of parts for the diesel injector market. We also have a strong will to further expand our market.”

On top of Wuxi Fortune’s automotive industry know-how, Mr Wang identified a gap in the market. He explained: “We saw there was a place for high-end turned auto part production and we understood the great potential it represented and we needed high-end, reliable and effective turning machines that would guarantee our ability to serve automotive customers.

“We knew that using advanced production equipment and technologies would help identify us as an excellent supplier, allowing us to deliver parts earlier than expected and even become an exclusive supplier of some specific parts.”

Higher efficiencyMr Wang wanted multi-spindle turning machines to gain higher efficiency, greater product consistency and lower manpower and production costs and compared several turning machine manufacturers before purchasing from Tornos.

He said: “At the time, multi-spindle turning machines were quite new in the Chinese market, but we are committed to being at the forefront of technology.”

“Now there are two MultiSwiss 6 x 14, one MultiSwiss 8 x 26, an SAS 16.6 and a MultiSigma 8 x 28 for small size precision parts. Our Tornos machines are reliable and efficient. The company provides completely integrated services, application knowledge, machine maintenance, training and spare parts to the Chinese market.

“The Tornos machines and services enable us to serve our high-end customers and maintain our competitiveness.”

The collaboration with Tornos helped pave the way for Wuxi Fortune to become the exclusive, world-wide supplier of a diesel injector pin shaft (pictured) to a leading automotive technology company with 2018 sales approaching 80 billion euros.

The 23mm long part has a maximum outer diameter of 9mm and a minimum groove diameter of 1.3mm and requires a tolerance of +/-0.03mm on the outer diameter.

Mr Wang added: “Tornos wouldn’t let us face a brand-new machine and all of its challenges alone. They quickly delivered the machines and helped us produce the sample part. THe machine tool supplier also supported us by finishing the required quality inspections and smoothly passing our customer’s evaluation. From the first contact between Tornos and Wuxi Fortune to confirmation of the processing solution at the early stage, it only took about two months.”

He concluded: “Our partnership with Tornos has built a solid foundation for our development and expansion in the future.”