Mitsui Seiki, which is represented in the UK by Market Harborough-based

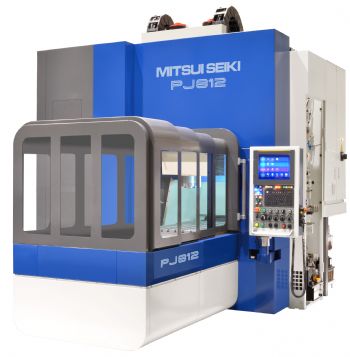

Kyal Machine Tools Ltd, has launched a new series of CNC vertical machining centres.

Called the ‘J series’ (for Jig), they have been designed for machining medical, optical, mould and die, and aerospace parts.

These machines provide a positioning accuracy and repeatability of ±1µm and incorporate a thermal compensation system with sensors on the machine faceplate and inside the spindle to minimise the effects of temperature changes on part accuracy and cut temperature-generated displacement by 60%.

This system also reduces Z-axis thermal growth and deflection by 30%, while cooling systems for slideway lubrication and ball screw cores stabilise axis-feed precision.

Meanwhile, mechanical design features that maximise machine rigidity and accuracy include hardened and ground box slideways, as well as ‘contact elements’ that enhance acceleration and reduce stick-slip.

Furthermore, the Z-axis has been engineered to offer a level of static rigidity that is six-times greater than that of a conventional Z-axis arrangement.

There are four basic machines in this new series: the PJ812 (PJ for Profile Jig) has a work envelope of 1,200 x 800 x 500mm, a maximum workpiece size 1,200 x 800mm, a table load of 1,500kg, spindle speeds from 10,000 to 30,000rev/min and ATC capacities of 60, 90 or 120 tools; the J1220 has a work envelope of 2,000 x 1,250mm x 500mm, a maximum table load of 3,000kg and spindle speeds from 10,000 to 15,000rev/min; the J1230 has a similar specification but a larger X axis (3,000mm), while the J1625 has a work envelope of 2,500 x 1,600 x 500mm and a maximum table load of 6,500kg.

All of the machines feature a full enclosure and various coolant system options.