Talisman Plastics

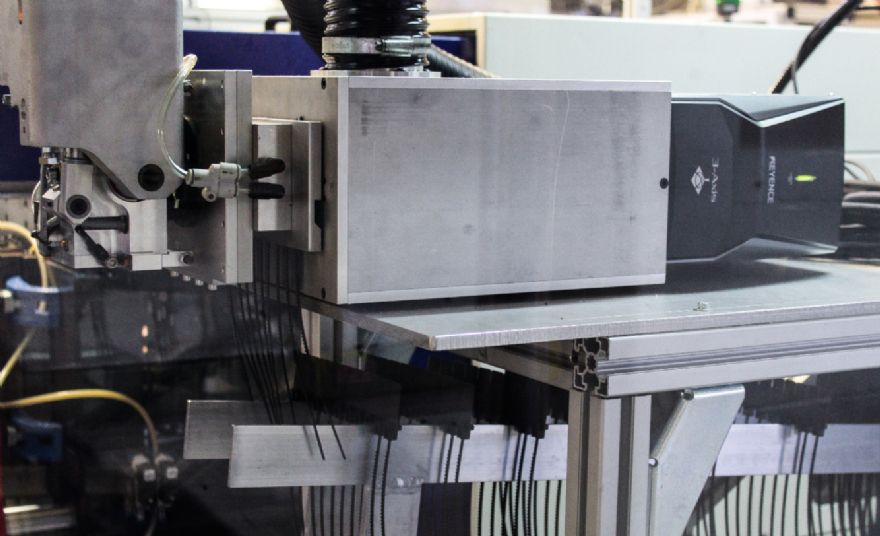

Talisman Plastics has invested in a new Keyence hybrid laser marker to improve its in-house printing capability, supplied by Milton Keynes-based

Keyence UK & Ireland Ltd.

The hybrid laser, comprised of a YVO4 crystalline material and a conventional fibre, transfers to the plastic target with heightened accuracy, meaning Talisman can now offer printing of barcodes, QR codes, logos and imagery onto its popular Taliloc, Enviroloc, and Easiloc products.

James Mulvale, business development manager, said: “The acquisition of the Keyence laser marker will provide a whole new level of customisation potential for our customers. Our choice of Keyence’s laser marker ensures we can provide the best possible print quality on our products.

“With the hybrid laser we get much clearer and crisper printing without reducing cycle times. We have invested in the new machine after looking at products from several manufacturers, but it became clear that Keyence could provide a laser that found the perfect balance of power as to clearly mark the seal but not burn through it.”

The new Keyence MD-X1500 Series achieves a peak power of 200kW, which is approximately twice that of conventional YVO4 lasers and it combines this with a short pulse width to minimise the damage caused by heat transfer to the target.

The three-axis control means that during the printing process, any distortion of character shape is eliminated, and even at the edges of the printed area, the laser provides perfectly focused marking and cutting with high accuracy.

Keyence’s MDX series laser marker was installed at Talisman’s Malvern plant in July, with the laser company providing training to all injection setting staff on using the software, which both programs the print design and verifies that the print has been carried out accurately, ensuring QR codes and barcodes function properly.

Nathan Flanigan, senior project engineer, said: “Working with the new Keyence laser has given us the ability to be quick with engraving changes and makes the process of creating barcodes, QR codes and serial numbers effortless.

“The Keyence laser and its associated software required minimal internal training, which has created efficiencies on the shopfloor.”