Peterborough-based

Marlor Tooling, one of the UK’s leading cutting tool manufacturers, continues to benefit from purchasing a Rollomatic Shapesmart CNC tool grinding machine from Coventry-based

Advanced Grinding Solutions, as it expands its sales into the medical tool and instrument markets.

Still a privately-owned second-generation family business, Marlor is now located in a ‘state of the art’ production facility and has 12 CNC tool and cutter grinding machines at its disposal plus various other CNC machines including EDM, drilling and inspection machines.

Marlor are perhaps unique among UK tool manufacturers in that nearly all of the company’s sales are to other tool manufacturers and it sells directly to very few end users.

Production bottleneck

Martyn Cross, Marlour works director, explained that after identifying a production bottleneck they had looked at many CNC cylindrical grinding machines on numerous occasions over the last three or four years with the need for fast set-up times and flexibility to make high-precision tools before opting to purchase a Rollomatic MP3+ machine.

According to Mr Cross the Rollomatic NP3+ is possibly the most transformative machine purchase that Marlor has ever made. Small or large batches of tools are now all done in-house with an incredible surface finish and holding the tightest of tolerances.

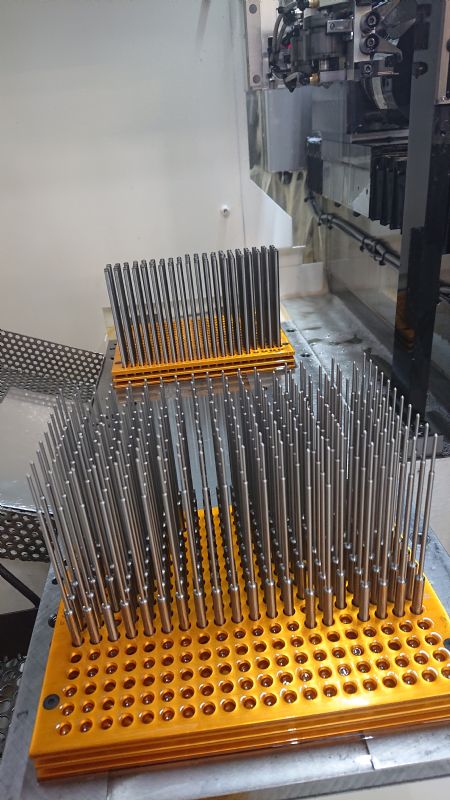

The Rollomatic machine has now enabled Marlor to enter into the market for medical tool blanks for the first time, with Marlor securing several high value orders including the one shown with the first batch of tools being 300-off that was produced automatically using the Rollomatic’s fully integrated robot loader for lights-out operation overnight.

Marlor is able to use the easy-to-set automatic loader overnight while manufacturing lower quantity special tools during the day. Mr Cross states that the quality, surface finish and repeatability from the machine is ‘stunning’, while the extended wheel life and dressing frequencies have been ‘a revelation’.

Cycle times have been dramatically reduced with Marlor citing another example of a long-length through-coolant drill for an aerospace application that used to take it 7min to manufacture as compared with a new time of just 2min on the Rollomatic machine.

Peel grinding

Peel grindingIn quantifying improvements in quality, Marlor has found that the Rollomatic machine easily holds tolerances of under 3um on tool diameters over larger batches of tools which it simply couldn’t achieve before.

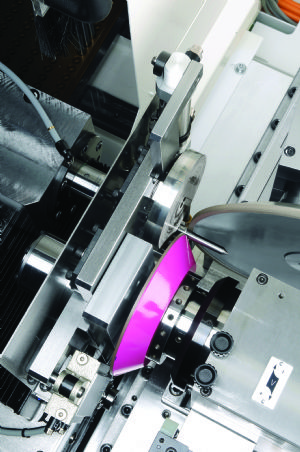

The company’s ShapeSmart machines are designed for grinding tool blanks and similar stepped cylindrical components and are based on the method of peel grinding — a technology invented by Rollomatic.

This new generation of cylindrical grinding machine has been improved to offer even more advantages for fast set-ups and superior grinding quality, including both rough and finish grinding in a single automatic operation for diameters up to 25mm, with a Renishaw probe handling length positioning.

Mr Cross concluded that in the months since its installation, Marlor has come to rely on the Rollomatic machine and that he cannot now believe how the company has managed without one for so long; the three-year parts and labour guarantee and the excellent technical and service support has given Marlor complete confidence that it have purchased the very best grinding machine for its requirements.

The NP3+ has contributed to a significant saving on production lead times, allowed rapid response for urgent jobs needing CNC cylindrical grinding, and enabled the company to take back full control by bringing all tool blank grinding in-house.