New software to improve the control and use of robots has been developed and launched by

Igus, the global manufacturer of energy chain systems and polymer plain bearings, which enables robots to be programmed and controlled with ease and also helps customers choose the robot that best suits the needs of their business.

Igus, which has its UK base in Northampton, has three low-cost automation solutions in its portfolio: Robolink robotic arm, delta robots and linear gantry robots.

Matthew Aldridge, Igus UK managing director, said: Our roots are in mechanical engineering, but as the igus range has evolved to include automated sub-assemblies, this new software is the next logical step for us.”

“Software plays a key role in the development of robotics and our simple and intuitive robot control system enables users to create their own program and also identify the Igus robot that is best suited for their application – before even making a purchase.”

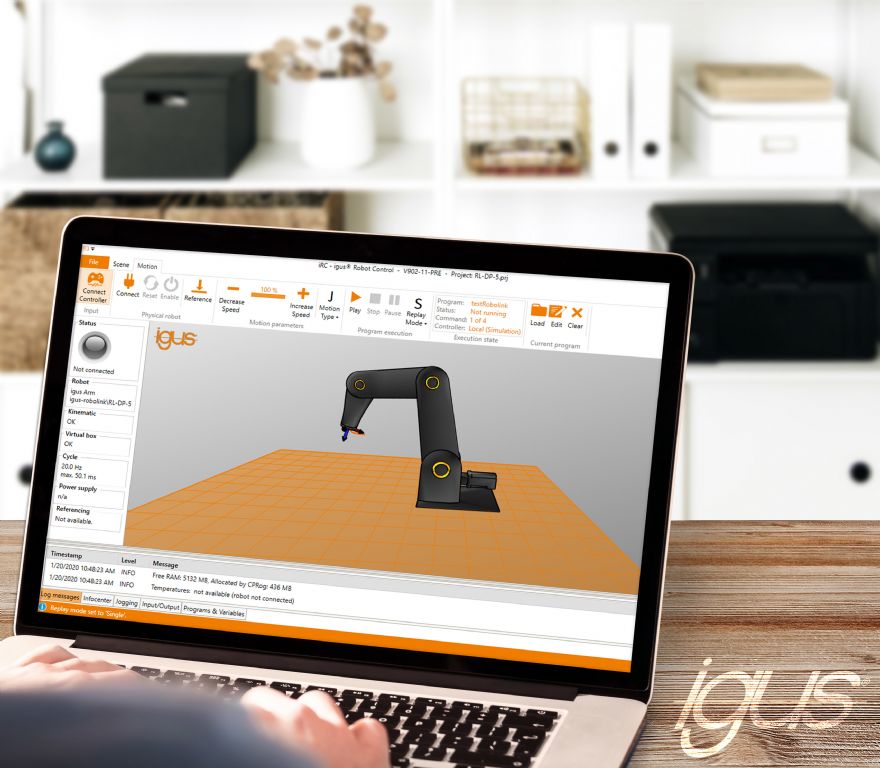

The Igus robot control, which is free-of-charge and license-free, is available online and includes a ‘digital twin’ - a virtual replica which can be programmed and taught to move and behave intuitively.

This programming can later be applied to the physical robot – whether it is picking up goods from a box, helping to take samples or even dispensing cans from a machine

The complete hardware package is available at a very low price point. For example, a drylin twin-axis gantry robot with an integrated controller in a control cabinet is available for £4,500.

Easy programming of robotsWith Igus robot control, the user can freely move all axes of the digital twin via a 3-D interface. A ‘teach-in’ function means the robot can be easily programmed, even without a robot connection.

Firstly, the user must manually move the robot to the initial position and then specify how it is to be moved. The process must be repeated until the desired motion profile is created. Matching end effectors, such as grippers, can easily be added, with the centre point adjusting automatically.

Virtual boxes or perimeters can also be installed to, for example, to prevent the robot from colliding with a machine. The Igus robot control can also be connected to a higher-level control system, either via interface communication with digital IO or via ethernet cable using an IP address.

Engineers at Igus are continuing to develop and enhance the software to offer cloud services such as vision integration, remote commissioning and online training for a small cost, which customers will be able to book online.

Further services such as image evaluation via webcams or bin picking solutions are also being planned.