Siemens Digital Industries Software

Siemens Digital Industries Software is expanding its ‘ecosystem’ for industrial additive manufacturing (AM) through partnerships with Morf3D, Sintavia and Evolve Additive Solutions.

Through these collaborations Siemens is adding support for new methods of AM production, further strengthening its ‘end-to-end solution’ for industrialised additive manufacturing as part of its ‘Xcelerator portfolio’ of software and services.

Over the last few years, Siemens has “gathered momentum in the additive manufacturing industry and is working to drive innovation in this critical market”.

Through key partnerships, acquisitions and other initiatives, the company has not only kept pace with the estimated 25% annual AM market growth but exceeded it over the last three years.

These new partnerships are the latest steps in Siemens’ ongoing work to expand access to the latest knowledge and technology to accelerate the adoption of industrial AM.

Siemens is collaborating with Sintavia, a leading metal additive manufacturer, to connect all phases of the AM process and increase automation across these processes for optimal efficiency.

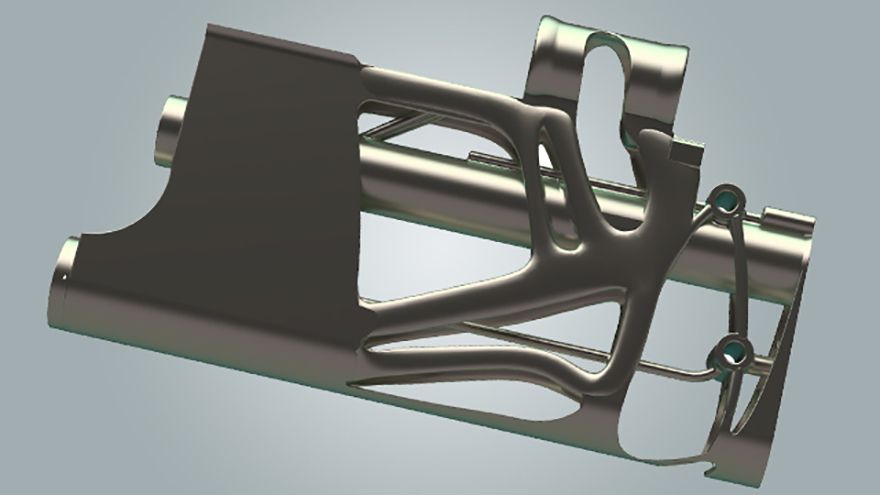

This development will be of particular benefit to the aerospace and space industry. Siemens agreement with Morf3D, an additive engineering and manufacturing service provider,will help in the application of Siemens’ AM software to the design, engineering and production of metal-based product across a variety of industries.

Meanwhile, Siemens’ agreement with Evolve Additive Solutions, an AM machine developer whose ‘pioneering’ STEP technology applies polymer onto rollers like a 2-D paper printer, will see the latter equip its machines with Siemens’ AM software so that they can ‘optimise build preparation’; this includes part slicing and nesting, as well as global production planning, scheduling and execution.

Aaron Frankel, vice president of the AM programme for Siemens Digital Industries Software, said: “Over the past year, through acquisitions and technology advancements, the launch of the new Siemens Additive Manufacturing Network and these relationships, we have continued to expand our ecosystem for additive manufacturing, which will help us enable all our customers to be successful adopting industrialised additive manufacturing.

“These key partnerships can help move us forward to enable customers to not only prototype but also manufacture products at scale.”