Creaform

Creaform, a leading global provider of portable and automated 3-D measuring solutions, has installed a second robot-controlled measuring system at

Walter Automobiltechnik GmbH (WAT) in Germany.

WAT is a system supplier of metal assemblies for the automotive industry and focuses on complex welded assemblies such as motorcycle frames and engine mounts, with a great deal of its work including motorcycle frames, torsion struts and more destined for the BMW Group.

The company recently landed the contract for development and series production of the engine mount for BMW’s new fully electric Mini Cooper SE.

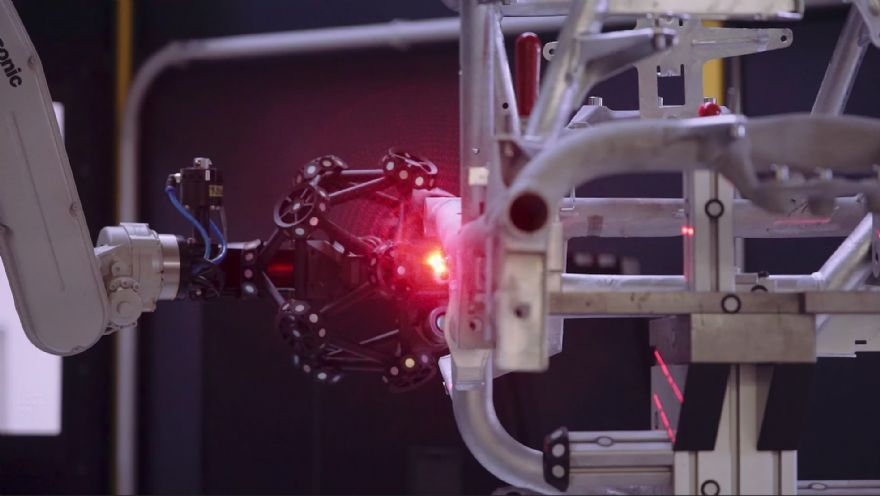

When the company needed to measure the vehicle’s complex tubular space frame, the company chose the MetraSCAN 3D-R, a powerful robot-mounted optical scanner that is Creaform’s automated quality control solution.

The WAT team uses MetraSCAN 3D-R for fully automated measurement of the complex tubular space frames with many connection points for peripheral equipment.

Due to the high-temperature galvanising required, 90% of the features cannot not be reworked and would immediately cause the production line to stop if they were not made exactly to specification.

Qualitative safe-guarding of the finished parts has to be conducted by carrying out 100% of the measurement of the series production within a given cycle time. A measurement report and 3-D scan have to be saved for each frame, for traceability purposes.

Tommy Laukdrej, WAT head of quality assurance, said: “We use two automated measuring cells with handling robots from Panasonic and the Creaform system, which consists of the MetraSCAN 3D-R scanner, C-Track optical camera system and VXelements scanning software.

“We also chose Polyworks from Duwe3d as the measurement evaluation software, because we have been using this with success and complete satisfaction for over 10 years. We are very satisfied with the measurement solution – it is easy to use and covers the largest possible measurement area with a high degree of accuracy.

“In addition, the measurements are independent of the accuracy of the robot. For WAT, this system is the future of automated quality control and quality assurance. It will definitely be used on new projects with a high degree of automation.”