A contractor to the medical industry suddenly saw its order for venilator components for intensive care units (ICUs) leap from 4,000 a week to over 18,000 in March last year at the start of the Covid-19 pandemic, and that increase in production now looks set to continue well into 2021.

Bolger Engineering, a custom enclosure and hardware specialist, has been manufacturing high-quality assemblies and fabrications as a trusted partner to its OEM customers for over 40 years. The company provides end-to-end solutions, including full contract manufacturing and supply chain services.

When the Covid-19 pandemic began, Bolger was contacted by its long-standing medical customer,

Medtronic – the global leader for ICU ventilators — it was already manufacturing components for Medtronic’s Puritan Bennett PB 980 and Puritan Bennett PB 840 high-performance ventilators at its purpose-built facility in Ireland.

The ventilators are primarily for critically ill patients requiring high intensive care. Due to the spread of Covid-19, demand jumped to unprecedented levels, and Medtronic needed to boost production five-fold, which meant Bolgers needed to ramp up its production.

Bolger sales manager Paul Collins said the company quickly identified ways of adapting to increase manufacturing capacity, including bringing in 35 new people and implementing different shift patterns to move to a 24/5 operating model.

It also became clear that the company’s Radan CAD/CAM software supplied by

Hexagon Manufacturing Intelligence would be a key enabler to manage what he described as a ‘major leap’.

“The design of the ventilators and individual parts didn’t change – but the challenge was to increase production by more than 500% which is expected to continue into the early part of 2021 at least. If there is another surge at any time, demand may increase again, so it is extremely difficult to say when things will return to normal.

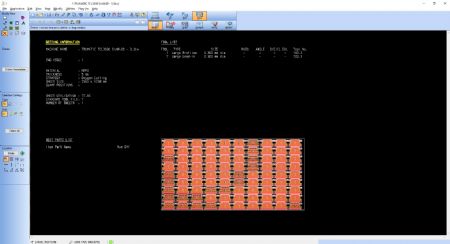

“We use Radan to program both of our Trumpf punching machines as well as our Trumpf laser cutter, so with over 18,000 components a week to produce for these ventilators alone, we knew the material usage and program optimisation were going to be crucial to meet such significant demand.

“Our programmers typically take a 3-D model or DXF drawing and import it into Radan to tool the part for either the punch or laser machines, depending on material thickness and complexity of the profile. They then nest and program the machine and Radan works out the best sheet utilisation.

“This is hugely important, as more often than not, material is the largest percentage of a job’s costs — optimising usage here helps us to be market-competitive.”

Radan software enables the user to optimise manufacturing nests, it also enables components to be profiled within extremely tight tolerances of +/-0.2mm.

Mr Collins continued: “That is very important as some components have 14 bends per part and we can very quickly see a high stack of tolerances when everything comes together at the assembly stage. This all has to be accurately produced on the machine through lasering or punching.”

While Radan is used to calculate the bend allowances, its LVD press brakes are programmed at the machine using the proprietary software.

Before Covid-19, a significant part of Bolger’s business was medical-related – supplemented by products for the building and construction sector, electrical cabinets and enclosures, and power generation sector.

“We also helped support one of our long-standing customers in the food and beverage sector with a Covid-19 related product which was looking for a hands-free solution for its hot water delivery systems. The company approached us with a concept drawing on 12 June and we produced a prototype within 72hr.

“Once approved an order for 1,000 units was immediately placed for delivery on the 24 June to facilitate both the opening of Ireland’s hotels, restaurants and cafés on 29 June along with the same openings in the UK on 4 July.

“That was an extremely fast turnround from concept to prototype approval to full production – all within a two-week window. Again Radan was a key enabler here.”

Radan is also used for generating quotations, but he says the company has recently installed Radquote to speed up the quotation process further.