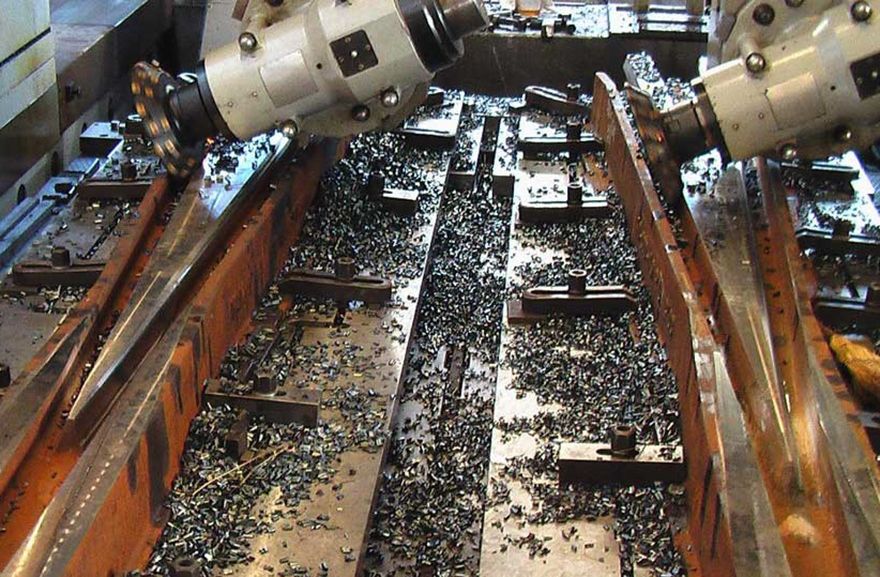

Railway switches during the production process

Railway switches during the production processRailway-focused cutting tools can often be complex if the machining of certain components is to be achieved in an efficient and reliable manner, which is why the majority of cutting tools for the railway industry are classed as ‘specials’ that have been designed with the customer and specific operations in mind.

That said, there are several tools available within the standard offering of

Dormer Pramet that can be used to support the production of various railway components.

For example, the company’s Penta HD and Econ HN are milling tools from its indexable range that can be used for various applications, including the machining of switches, base plates and wagon parts, such as frames, wheel axles and bogies.

Rail switches and crossings are the sections that guide trains from one track to another, and Dormer Pramet offers tools for machining switches in all major rail profiles. These include the 60E1 and 60E2 rail profiles, which are the most common, especially in Europe.

In the crossing part of the two rails, known as the frog, manganese steel (also known as Hadfield steel) is used, as it is ideal for high impact environments. Moreover, manganese steel is not magnetic and has a very high abrasion resistance, which is necessary because the crossing has to withstand the highest load on a railway track.

It is also a very tough material; and while it naturally has a low hardness (200-280HB), when it is machined the hardness increases to more than 350HB.

Another material used in the production of switches is bainite steel, which is much easier to machine, even though it is a harder material at 450HB. It is ideally suited to this part of the track due to its high strength and wear resistance (rail steels have to resist plastic deformation and rolling contact fatigue, as well as bending and thermal stresses during the welding processes and ‘renovations’.

Switch machiningWhen machining switches, one of the first operations is roughing the top and bottom sections of the rail. This requires the use of a large-diameter cutter that can undertake these operations with the fewest number of passes possible.

Both the Penta HD and Econ HN ranges have indexable cutters up to 315mm in diameter. Indeed, the Penta HD milling cutter was specifically developed with the machining of switches in mind.

Allowing operators to use the full power of their machines, the Penta HD with PNMU insert can be used for heavy roughing operations in a variety of materials, including steels, stainless steels and cast iron.

Offering depths of cut up to 10mm and a feed rate of 0.7mm per tooth, the range enables high metal removal rates and productivity. Its double-sided insert design with 10 cutting edges has ‘an available length of 100mm’, with each edge numbered for easier indexing.

In a recent test, a Penta HD with PNMU insets, M chip-breaker and M8345 grade was able to machine 4,600mm of track in 39min, with a cutting speed of 70m/min, a feed rate 0.33mm/tooth and an axial depth of cut of 7mm.

Another key feature of the Penta HD is the use of Dormer Pramet’s patented Sidelok system, which has been designed to provide quick and easy clamping and release of the inserts. With a large retention screw permanently remaining in the cutter body, inserts can be quickly changed enabling more machine time, further increasing productivity.

Base platesRailway operations where standard tools can be used include the machining of base plates — the connecting element that ensures the rail is securely attached to the tie or sleeper. Also, wheel set axles, break-pad connectors, beam bolsters and bogie frames all require machining to specific shapes.

For initial machining, face-milling cutters are usually the most suitable tool, removing large amounts of metal and creating a smooth flat surface and base, before specific shaping can be performed for interfacing with other components.

When machining the bottom part of base plates, for example, face milling cutters with diameters up to 160mm are often used. The Pramet Econ HN range offers a 45deg face-milling cutter, which is available in diameters from 25 to 315mm and includes the HNGX 06 and HNGX 09 inserts.

Designed to achieve high levels of surface quality, this range of indexable cutters can perform both roughing (up to 6mm depth of cut), through to finishing (up to 1mm depth of cut). Its inserts have 12 cutting edges, with a wiper option for when higher levels of surface finish are required.

Moreover, these cutters can be used to machine cast irons, as well as steels, while ‘high insert density’ ensures high productivity and longer tool life, along with lower cutting forces.

Furthermore, a differential tooth pitch and a unique geometry (F, M or R) for each operation, from finishing to roughing, along with an internal coolant supply, provides ‘high tool accuracy and quiet running’.