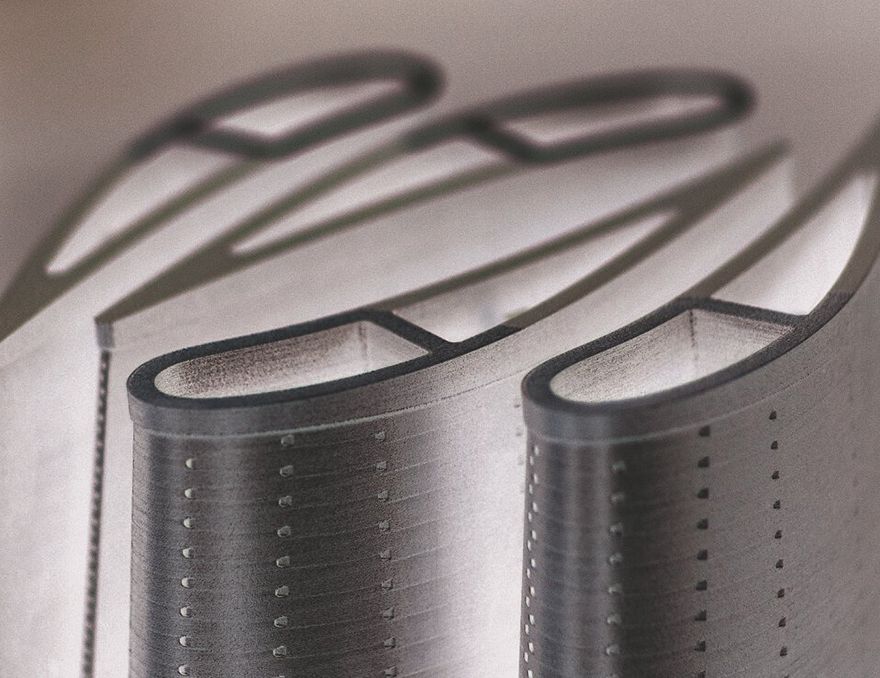

EOS NickelAlloy IN939: turbine vane segment. Picture courtesy of EOS

EOS NickelAlloy IN939: turbine vane segment. Picture courtesy of EOS Germany-based

EOS, a world-leading innovator of industrial 3-D printing technologies for metals and polymers, has added a new nickel alloy material to its growing and expansive list of metal powders available for use in powder bed additive manufacturing (AM).

The new material, EOS NickelAlloy IN939, is a nickel-chromium alloy that provides an excellent balance of strength in high-temperature settings, resistance to corrosion and oxidation, fatigue performance, and creep strength at temperatures up to 850°C.

EOS NickelAlloy IN939 offers greater tensile properties, validation, reliability, and crack-resistance than similar materials currently on the market and parts made with this material can be hardened after manufacture by applying precipitation-hardening heat treatments.

For processing on the EOS M 290 metal AM platform, all these qualities position EOS NickelAlloy IN939 perfectly for use in creating industrial gas turbines, (vanes, blades, heatshields), as well as microturbines, turbochargers, power industry parts and other energy industry applications exposed to high temperatures and extreme elements.

Dr Alex Hoffs, president of Power Systems Mfg, LLC (PSM), said: “PSM is excited to see the continued investments by EOS supporting 3-D printing applications in the energy industry. For gas turbine power plant operators, we believe flow path components additively manufactured with new advanced metal powder alloys such as EOS NickelAlloy IN939 bring the potential for significant operational flexibility improvements.”

Kevin Minet, EOS team supervisor metal materials and processes, said: “Material development is always driven by customer demand and very often is the result of a close customer cooperation. EOS NickelAlloy IN939 was developed to meet or even exceed the properties of casted nickel alloy.”

He concluded: “The PSM application scenario and their early success support the potential we see for this material for more industries and applications.”

In addition to the immediate availability of EOS NickelAlloy IN939 for the EOS M 290, there is a planned release for the EOS M 400-4 platform in Q2 2021, and other future platforms.