The latest 2021.1 version of the HyperMill CAD/CAM software suite from Bicester-based

Open Mind Technologies UK Ltd offers a wide range of new functions that provide even higher levels of surface finish.

In mill/turning, Open Mind now offers an option for simultaneous turning and high-performance cutting (HPC). Furthermore, a new function in HyperCAD-S allows users to easily align stock and model data, which is particularly useful before reworking additively manufactured parts.

Meanwhile, the latest ‘five-axis radial machining’ function now makes programming easier, allowing tool-paths for bottle, tube or exhaust shapes to be calculated even quicker by using a radial projection method, with an ‘indexed tilt per cut’ allowing each step to achieve the best possible surface quality.

Also, the standard integrated ‘high-precision surface mode’ achieves ultra-precise surfaces in the µm range, while ‘smooth overlap’ strategies are available to enhance surface finishes in transition areas.

A new ‘X-Y optimisation’ feature in the ‘3-D Profile Finishing’ function improves machining with X- or Y-axis infeed strategies, thereby optimising the ‘Smooth overlap’ strategy; if an area cannot be optimally machined in the X-axis on a steep wall, it is automatically machined in the Y-orientation to maintain a constant infeed. The optimised blending in the overlap area makes changes to the machining direction that are not visible on the workpiece.

The latest version of HyperMill now provides a new option for editing tool-paths; the ‘Edit tool-path’ interactive mode allows users to select and remove existing tool-paths at selected points and curves — or entire too-path sequences between two ‘G0 movements’.

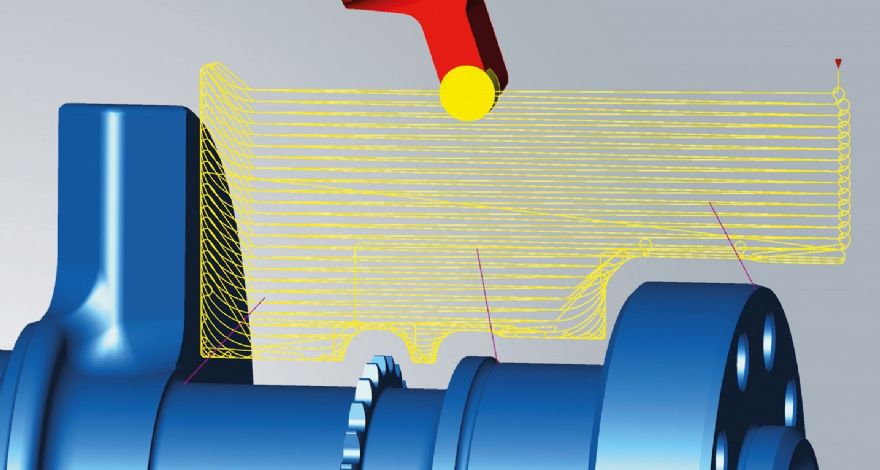

Moreover, the Mill-Turn machining module sees Open Mind applying its milling expertise to turning, by making it very easy to use high-performance tool-paths with optimised approach and retract movements during simultaneous turning.

Meanwhile, the integrated HyperCAD-S CAD software provides a new function that is particularly helpful when the workpiece to be machined differs only slightly from the stock.

In cases where a high-precision pre-cast part or an additively manufactured workpiece needs to be machined, the ‘align best fit’ function ensures that the CAD model of the workpiece fits perfectly with the stock model.

An algorithm automatically calculates the best possible alignment and the user can use various parameters to control exactly how the alignment should look.

Programmers can lock the translation and rotation axes as well as define a weighting between the individual matching points, thereby allowing, for example, meshes of stock or welding areas to be optimally and quickly aligned with the actual CAD model.