A family-run company,

Broanmain Plastics manufactures compression and injection moulded components used in various applications throughout many industries, including aerospace, electronics, railway signalling, filtration, and climate management systems.

Between two sites, based in Surrey and West Sussex, the company houses machinery with capacities up to 550 tonnes and a shot weight of up to 1,500 grammes, providing extremely high-production volumes in which consistency of the finished product is vital.

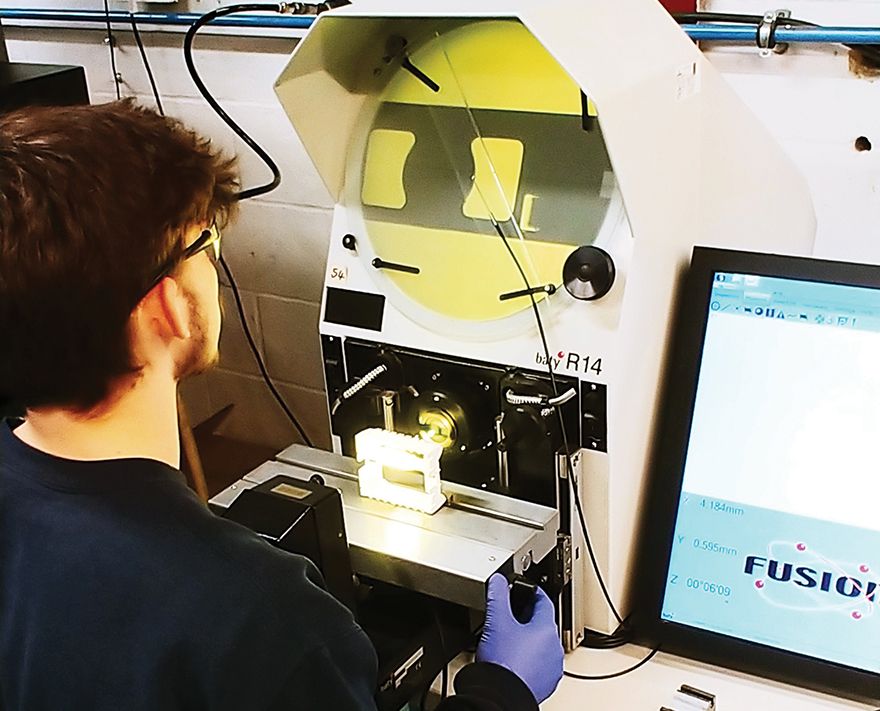

With injection moulding, it is possible to incorporate complex detail into the design of the part, which in turn necessitates close inspection to ensure strict quality standards are met. Looking to improve on the consistency of produced parts, and to work more effectively within time constraints, Broanmain Plastics recently invested in a Baty R14 profile projector — from

Baty International, which is part of the Bowers Group — to support its quality team in ensuring repeatable results.

The R14 is a bench-mounted profile projector that provides high-accuracy, non-contact optical measurement and inspection and a 175 x 100mm measuring range. Optical measurement offers effective non-contact inspection by using a light source that projects onto the part, casting a silhouette into the camera, allowing the instrument’s software to undertake a thorough inspection that can show even the most minuscule of faults.

Jo Davis, Broanmain Plastics’ managing director, said: “Quality is key for different reasons. For some, it is safety-critical, for others it is more aesthetic — but what is always required is a consistency. The Baty R14 makes the inspection process quick and easy; it has been an invaluable installation to both the quality team and the company as a whole.”

Kamil Stec, Bromain Plastics’ toolroom manager, added: “The parts we measure are often hard to fixture, but we have found that the align option in Baty’s Fusion software saves a lot of set-up time. There are also a lot of handy construction options available.”