While Mitutoyo is a world-leading manufacturer of precision-measuring equipment ranging from the ‘humble’ caliper to advanced vision-based measuring systems and 3-D coordinate measuring machines, Andover-based

Mitutoyo (UK) Ltd) — now in its 40th year of operation — also supports its customers with not only the supply of precision products but also a wide range of complementary services.

In addition to product training, IT support, calibration and repair resources, Mitutoyo (UK) also offers sub-contract measuring services.

While Mitutoyo’s Measurement Services department serves the sub-contract measurement needs of numerous large blue-chip businesses, the assistance currently being provided to FeTu Ltd helps to illustrate the inspection work undertaken by Mitutoyo for small and medium-size businesses.

Established in 2016, Elland-based FeTu has developed a ‘revolutionary green energy device’ that targets carbon reductions across a broad range of systems and industries. The company’s ‘disruptive technology’ is a continuous positive displacement machine that is suitable for a wide range of applications. It uses just two moving parts to operate ‘four anti-phased compression chambers’ and offers ‘low-loss conversion from potential energy to kinetic energy’.

As a relatively young business that is involved in the design, development and testing of its ‘roticulating’ technology, FeTu currently sub-contracts all of its manufacturing activities. Given the extremely demanding dimensional tolerances and the critical geometries of the device’s two moving parts, FeTu’s founder and CEO — Jon Fenton — recently searched for a source of independent, high-precision inspection, finally selecting Mitutoyo’s Measurement Services.

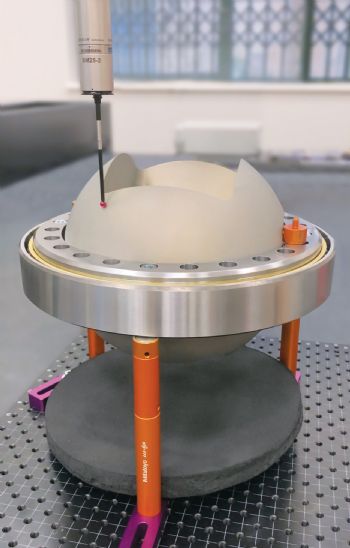

In-depth inspectionPrior to the assembly and testing of each new iteration of FeTu’s designs, Mitutoyo’s staff use one of the company’s Crysta-Apex S Series CNC coordinate measuring machines to perform a range of in-depth, high-precision inspection routines and subsequently provide comprehensive inspection reports. Based on these, FeTu can make further developments.

Highlighting the benefits of working with Mitutoyo Mr Fenton said: “As tradition has it, in visualising an ‘engine’, ‘pump’, ‘compressor’, ‘turbine’ or ‘expander’; we imagine five discreet machines which all appear and function in very different ways. The beauty of our technology is that it can accomplish each of these functions in a much more efficient way than they are performed by current traditional means.

“The two dynamic parts of the FeTu system do not make contact but run so close to each other as to make an effective a seal. The sealing effect is aided by the leakage paths being so long that they stagnate flow. To ensure that an efficient seal is achieved, the system’s two high-precision moving parts have extremely tight dimensional tolerances.

“Therefore, a major aspect of our design, development and testing activities has been achieving the required levels of accuracy that allows efficient and reliable sealing to be accomplished.

“The high-precision CMM inspection work undertaken by Mitutoyo and the comprehensive inspection reports supplied to us, related to the accuracy of the moving parts and other critical aspects of our designs, has been invaluable. In addition, the speed and in-depth nature of the feed-back we have received from Mitutoyo has helped us to shorten our developments times.”

Andrew Fifield, the manager of Mitutoyo’s Measurement Services department, says it supports UK companies that are involved in a wide variety of industrial sectors. “Typically, businesses are helped on occasions when demand for their QA inspection exceeds their in-house capacity, or when the required measurements exceed the capability or physical capacity of their metrology equipment.

“Our team uses a range of ‘state of the art’ metrology equipment that enables the most demanding of components to be measured, profiled, analysed, scanned, programmed or compared to CAD data. We can also accommodate all QC, QA production or SPC requirements.

“It appears that Jon Fenton and FeTu are on the verge of introducing a phenomenal technical breakthrough that has applications for many industrial sectors. All at Mitutoyo are proud to have played a small, but important, part in FeTu’s technology developments and look forward to witnessing the company’s imminent success.”