The latest release of

CoreTechnologie’s 4D_Additive additive manufacturing (AM) software (version 1.3) is equipped with new features to meet the increased demands of small batch production of 3-D printed parts.

The software, which is equipped with new functions, is specifically dedicated to the current processes and higher requirements of the small batch production of 3-D printed parts.

For the first time, it provides an application programming interface (API) for Hewlett Packard and Photocentric machines to enable a seamless and time-saving process to send the slicing data generated on the computer directly to the 3-D printers.

Another highlight is the revised texture module, which can be used to quickly and easily enhance the surfaces of CAD models as well as STL bodies with various surface textures. In addition to the option of applying users own designs, there are over 5,000 predefined patterns to choose from.

In addition, logos and QR codes can be generated and texts as well as incremental part IDs can be applied on the printing parts.

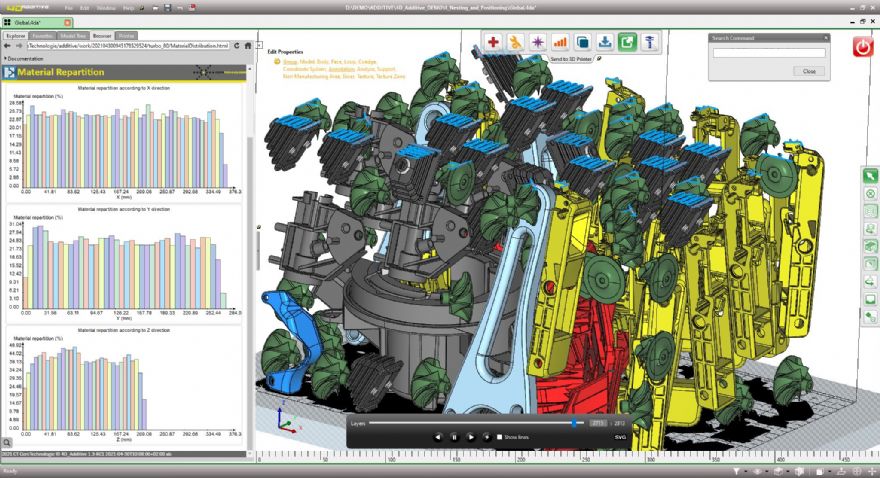

Especially for powder bed machines, the so-called nesting functions have been improved to ensure fast and thermally optimised filling of the build space. The new version uses AI algorithms to selectively fill free areas in the build space and ensure constant slice areas of the individual layers.

An extremely fast calculation speed results is possible by accessing all available processors on the computer. It is possible to prepare the nesting of parts manually and optionally define the degrees of freedom around the X, Y and Z axes individually for each part.

The new position correction for SLS and SLM parts serves to avoid surface defects caused by zig-zag movements of the laser on the bottom and top slice layer of the parts. For manual positioning, the new software version offers an intelligent Powercopy function using a voxel representation of the models for high packing density.

Meanwhile, an automatic repair function for scan data delivers closed and homogeneous STL models in the shortest possible time. The functions for cutting CAD and STL models have also been extensively revised, with various joining patterns such as pins or grooves now also available.

The software reads all CAD formats as well as tessellated formats e.g. Catia, Nx, Solidworks, Creo, Step as well as STL, 3mf and Amf. Dimensions, tolerances and views, as well as all attributes and design elements from the CAD data are also displayed.

By this means, all manufacturing information is available for the 3-D printing process. The results of the preparation process can be saved as STL, 3mf, Amf or even as exact Step models. After the multiprocessor based slicing e.g. Sli, Slm and Slc formats as well as jpg and png bitmaps or Svg vector graphics can be saved.

The software follows the philosophy of a standardised as well as open system and as a result offers a solution for all processes with extensive possibilities for individual customisation. The graphical user interface (GUI) is easy to use and presents the workflow for preparing 3-D parts for AM in the form of sequential workshops.

Current AM processes with their specific requirements can now be easily implemented based on the open system of the new software version of 4D_Additive.