Headquartered in Aberdeen, the oil and gas capital of Europe,

L&N Scotland is a leading manufacturer of subsea production flow spools, chemical injection lines, and control systems equipment. Given the safety-critical nature of its manufactured products, the quality of the ISO 9001-registered business’s output is all important.

To provide greater control of its production processes and to help the company to maintain ‘Critical to Quality’ (CTQ) product attributes, L&N Scotland’s staff undertake a comprehensive range of inspection activities.

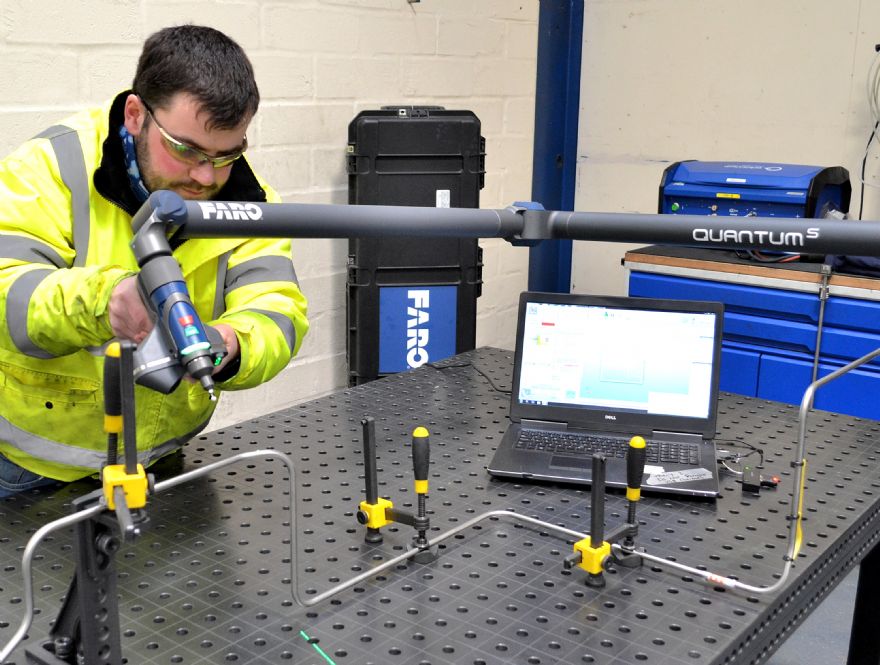

The mainstays of the company’s inspection regime are its recently-purchased Faro QuantumS ScanArms from Rugby-based

Faro Technologies UK Ltd. The three ScanArms were bought in accordance with L&N Scotland’s policy of regularly updating its inspection equipment.

Robert Knowles, an L&N Scotland quality engineer, said: “L&N Scotland has in-depth experience in engaging in engineering collaborations with the global subsea sector. As we operate in a fiercely competitive and ever-changing industrial sector, we are committed to continually adapting to best meet our customers’ evolving needs and to provide them with products and services of the highest quality.

“In addition to our quest for constant improvements, our growing production volumes recently prompted the purchase of our new Faro QuantumS ScanArms. As the equipment is very accurate and stands up well to the rigours of shopfloor use, we have been users of Faro products for several years.

“Although our previously used Faro portable CMMs were still serviceable and able to meet our dimensional and tolerance demands, the improved precision, speed and ease of use of the QuantumS ScanArm convinced us to bring our inspection technology and related software right up to date.

“Our three new ScanArms, which are now in constant use, have enhanced our precision capabilities and considerably speeded up our inspection throughput.”

Pipe measurementAlthough L&N Scotland’s new ScanArms have delivered significant benefits to several company departments, it is in the area of subsea control system manufacturing that they have provided the biggest advantages.

Adrian Chalmers, one of the company’s QC inspectors, said: “We produce complex pre-manufactured subsea control system kits that feature a significant number of very long pipes. These feature intricate compound 3-D shapes with demanding dimensional tolerances. Further complicating matters is the fact that the pipes are located in close proximity to each other.

“High-precision inspection is vital as our kits are dispatched across the globe, and on arrival the various pipes are expected to connect and assemble without the need for rework or adjustment. As some of our pipes are over 10ft long, even the smallest angular error at one end of a long pipe could cause an inaccuracy that can be measured in inches at the opposite end, causing it to foul a neighbouring pipe.

“Therefore, to guarantee ease of assembly and to make sure that no pipe-to-pipe contact occurs, part of my duties is to ensure that all of our pipes are efficiently and precisely manufactured — and carefully inspected.

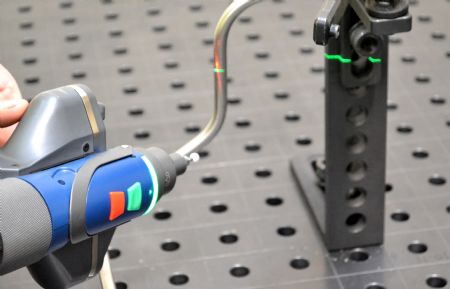

“We specified our three new ScanArms fitted with Faro Prizm laser probes. Because the pipes in our kits can spring and flex under physical inspection, the extremely accurate non-contact scanning capabilities of our new ScanArms have provided us with a major advantage.

“We can now precisely scan tubes with the most complex of shapes, compare our findings to their CAD models and, if necessary, instantly send any required correction information back to our CNC bending machine. Moreover, we can now reverse engineer existing pipes and create precise models for future use.”

‘Flexible’ useThe QuantumS ScanArms purchased by L&N Scotland can use both tactile probes and the Faro Prizm laser probes, with users able to switch between each of these probing elements without needing to remove either component.

For example, it is possible to digitise simple component features with the ScanArm’s hard probe, then seamlessly laser scan freeform areas. Moreover, Faro’s non-contact solution enables high-precision scanning to be carried out on a variety of surface materials — regardless of contrast, reflectivity or part complexity — without the need for the application of special coatings or target placements.

Complementing the ScanArms is Faro’s CAM2 software, an easy-to-use intuitive ‘3-D measurement platform’ that helps users to efficiently perform quality assurance and inspection tasks. Faro says this “feature-rich application-focused software can manage repeat inspection routines and provide live trend and statistical process control (SPC) analysis”.

Furthermore, because Geometric Dimensioning and Tolerancing (GD&T) is increasingly included in oil and gas related drawings, it helps L&N Scotland that this feature is also included in Faro’s CAM2 software.

Mr Knowles concluded: “The training provided by Faro meant that our operators were able to make use of our ScanArms’ range of capabilities in a very short time. While further improving our already impressive accuracy capabilities, the use of our ScanArms has enabled us to considerably simplify and speed-up numerous inspection activities.”