Camberley-based

Bowers Group has recently achieved ‘Made in Britain’ accreditation for its market-leading bore gauges which it manufactures in West Yorkshire. To maintain the high quality and accuracy of its famous bore gauges, the compay uses a measurement solution from within its very own range of products — a Baty profile projector.

As part of the Bowers Group, Burgess Hill-based

Baty International also manufactures its profile projectors and vision systems in the UK, achieving its own ‘Made in Britain’ accreditation in 2020.

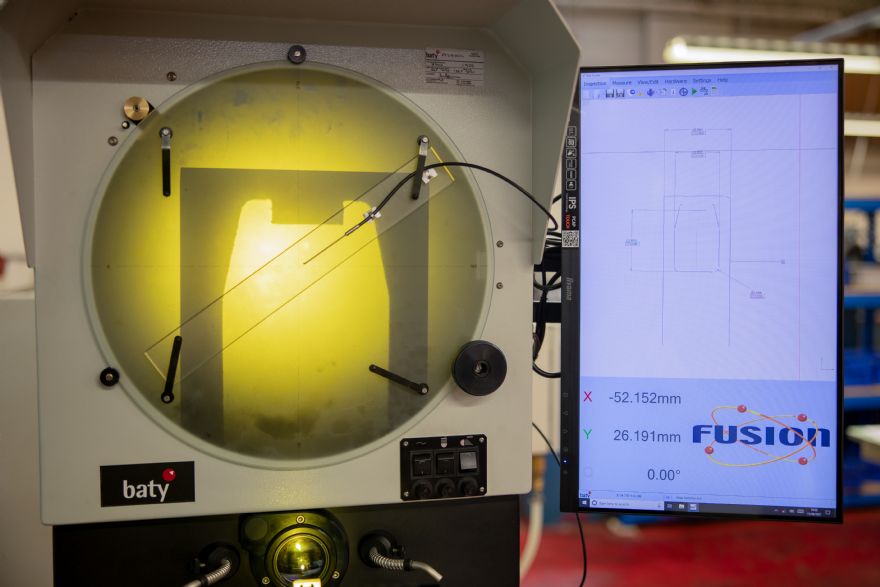

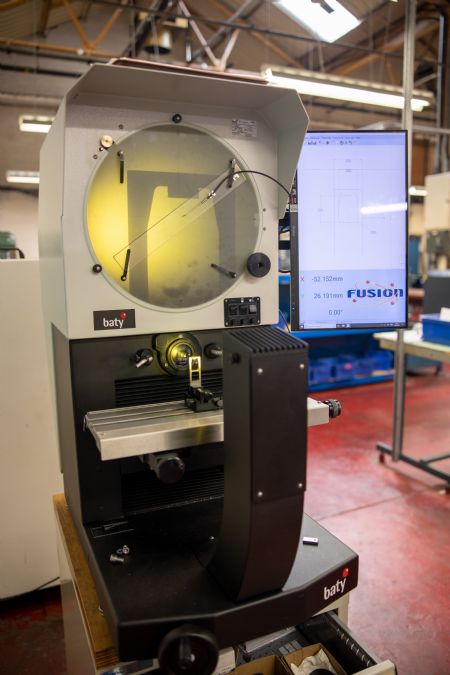

During the manufacturing process, Bowers uses the Baty R400 profile projector and complementary Fusion software to ensure the accuracy of all manufactured components. This includes parts for analogue bore gauges, digital bore gauges, and the popular XT3 Digital Pistol Grip bore gauges.

The Baty profile projector is also used to check the quality and accuracy of measuring heads for threads, grooves, splines, spherical, and deep holes, in addition to completely bespoke custom gauges manufactured by the application gauging team at Bowers.

Pav Maan, Bowers application gauging supervisor, said: “We use the Baty R400 profile projector and the accompanying Fusion software to check the quality of our manufactured products on a daily basis, including our three- and two-point anvil heads.

The Baty R400 profile projector produces a focused, sharp image, allowing us to measure the shape and form of anvils, as well as using the software’s sophisticated graphical reporting to create dimensioned drawings.

Dimensions within the specified tolerance are shown on the screen in green, while any dimensions out of tolerance are shown in red — that means we have an immediate visual status of the measured part.

Accuracy is very important to us here at Bowers Group. The Baty R400 makes measurement easy and saves a huge amount of time and effort by offering accurate, repeatable, and fast measurements.”

Ensuring accuracy and qualityOnce the anvils have been through the grinding process, the measurements are checked on the Baty profile projector to ensure accuracy and quality. The radius is measured, as well as angles and lengths to ensure accuracy to three decimal places.

The Baty R400 bench mount profile projector combines high-accuracy, non-contact measurement and inspection with a large 300 x 150mm measuring range and boasts a long list of standard features, such as a 400mm screen with 90deg cross-lines, chart clips and digital angle measurement with a resolution of 1min of arc.

Optimum profile illumination is delivered by an efficient lamp with a green filter, whilst surface illumination is achieved via high-intensity fibre optics. The R400’s sturdy work-stage features two machined T-slots to allow even the most awkward or fragile workpieces to be held securely throughout a measuring routine. To facilitate accurate thread form projection, the R400 also allows for a helix adjustment of the light source.

Acquired by Bowers in 2010, Baty offers a range of metrology instruments from hand tools to vision systems. The Baty ‘Shadograph’ series has become an industry-standard in profile projectors, with products still manufactured in Sussex.

The application gauging team at Bowers offers a range of measurement solutions, including threads, grooves, splines, sphericals, and deep holes, as well as completely bespoke custom gauges to solve complex measurement problems.

These application heads can be fitted directly onto the XT range of internal micrometers to create a flexible, modular measuring system. The extended mechanical travel of the XT range means that special heads can also be manufactured to accommodate even the most awkward measuring problems.