The new XYZ SS 65 is the first high-specification sub-spindle turning centre to be available from XYZ Machine Tools

The new XYZ SS 65 is the first high-specification sub-spindle turning centre to be available from XYZ Machine ToolsDevon-based

XYZ Machine Tools has extended its extensive range of machine tools with the addition of the XYZ SS 65 twin/sub-spindle turning centre — the company’s first foray into multi-spindle turning centres. The new machine has been introduced to meet the demand from customers looking for increased productivity and reduced spindle downtime.

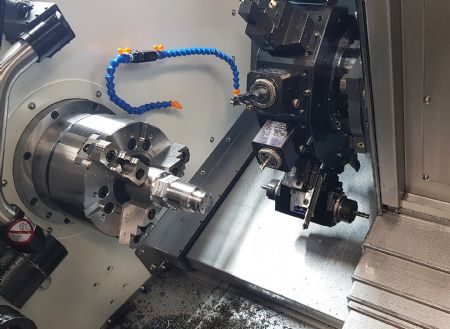

The XYZ SS 65 is a well-specified machine, built to the highest standards, that can significantly reduce cycle times and keep spindles operating at maximum efficiency. The 16.5kW 4,000rev/min main spindle (pictured left) has a 65mm bar capacity, with 200mm diameter chuck as standard and this is complemented by the 150mm chuck on the 11kW 5,000rev/min sub-spindle (pictured below), which has a 52mm bore.

Its German-built Sauter 12-position turret has live tooling at every station, with 100mm (+/-50mm) Y-axis travel. Contouring is facilitated by the C-axis on both spindles which are equipped with a brake to allow substantial milling cuts to take place. Maximum turned diameter is 380mm and the Z-axis travel is 520mm, providing a significant working envelope.

Ability to machine parts in one-hitThe new sub-spindle turning centre is supplied with a Siemens 828D ShopTurn 15in touchscreen control which can be enhanced with optional Siemens offline programming and CAD reader software if required. All of this is built around a 30deg slant-bed design with linear ways for faster positioning speeds. Its solid cast construction means the XYZ SS 65 weighs in at 5,000kg, a solid base from which to maximise performance.

Nigel Atherton, XYZ Machine Tools managing director, said: “This twin/sub-spindle turning centre with live tooling and Y-axis arrives at a time when companies are bouncing back from the restraints of the Covid-19 pandemic, but also a time when finding skilled labour is challenging. The ability to machine parts in one-hit, thereby reducing part handling and idle time, will enable machine shops to maximise productivity and spindle up-time while making use of available labour.

“At around £120,000 the high specification is on offer at a tempting price point for either existing sub-spindle users looking to upgrade or those looking to take their first steps into benefitting from the technology.”

The XYZ SS 65 is available for demonstration at XYZ Machine Tools’ Burlescombe headquarters with a limited number of machines available ex-stock for those with urgent requirements.