Tamworth-based

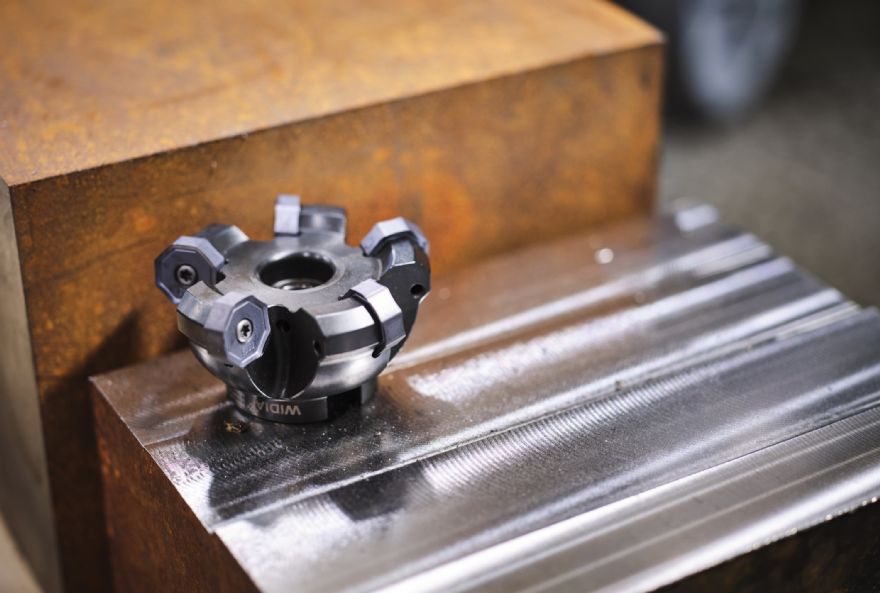

Industrial Tooling Corporation (ITC) has introduced the new Widia M1600 face mill for roughing to semi-finishing operations in steel, stainless steel, cast iron and nodular iron materials. With 16 cutting edges and a smart insert design, the M1600 performs in various machining conditions including low-power machines, unstable, non-rigid set-ups, long overhangs, weak machines or weak fixture conditions.

Anna Kim, Widia indexable milling global portfolio manager, said: “Face milling is one of the most common machining operations, so we designed a versatile and cost-effective solution that delivers substantial improvements in metal removal rates in steel and cast iron for our customers.

“The M1600 represents a turnkey solution for general engineering, energy and automotive customers who want to reduce their face milling tooling inventory and increase their machining outputs.”

The 16-edged, precision-ground insert with a positive geometry enables low cutting forces and low power consumption resulting in higher tool life and an excellent cost per edge. The M1600 has one universal insert geometry in three versatile grades: WP35CM, WK15CM and WU20PM.

The WP35CM grade targets all types of steels, while the WK15CM grade is designed for cast-iron materials and performs best in dry applications but can also be used in wet conditions. The universal WU20PM grade can be used for the machining of steel, stainless steel and high-temperature alloys in both dry and wet applications.

The ‘smart’ insert design features a seating surface below the cutting edge that promotes smooth chip flow and reduces cutting forces on the tool. The insert also has a curved cutting edge and is axially positive resulting in reduced power consumption. These key design features coupled with 16 cutting edges make M1600 an economical face milling option.

M1600 face mills are available in six metric diameter ranges between 50 and 160mm. Imperial diameters will follow in the autumn. Orders for the M1600 bodies and inserts as well as other Widia metal cutting tooling can be placed through Widia authorised distribution partners.