Cutting tool manufacturers have always had the inconvenience of producing solid carbide and PCD cutting tools on two separate machines — that was until

Vollmer UK Ltd introduced its VHybrid concept. Now, the company has eradicated this issue for cutting tool manufacturers with its flexible new VHybrid 260 solution that can grind carbide tools and erode PCD tools — all in one machine.

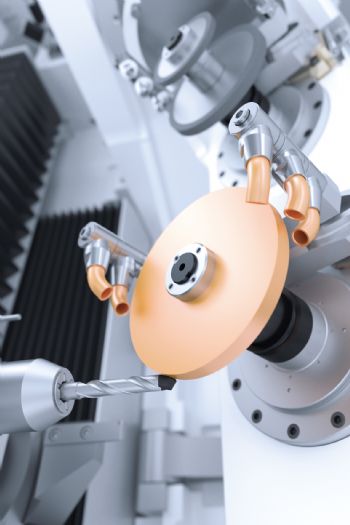

The Vollmer VHybrid 260 combines the technologies of a grinding machine and an erosion machine, making it possible to switch between the two functions with ease. Utilising Vollmer’s unique multi-layered machining technology that was first proven in the Vgrind series of machines, the vertical alignment of two spindles is an innovative arrangement that allows the grinding and electrode wheelsets to precisely pivot the C axis to ensure optimal results can be achieved.

This configuration allows users to combine both processes. If the tool requires grinding and erosion, the VHybrid 260 can create one complete and highly efficient machining process for all tool production requirements.

The multi-layered spindle configuration allows the efficient grinding of carbide tools with diameters of up to 150mm on the top spindle whereas the bottom spindle can accommodate both grinding and erosion. This enables the efficient machining of carbide or PCD tools up to a diameter of 150mm thanks to the high-performance and finely tuned Vpulse EDM erosion generator that maximises productivity and performance while reducing production costs.

This ultra-precise erosion generator delivers surface finishes to roughness of 0.1μRa for the best possible cutting tool quality whilst electrode calibration and wear control that combines with a dressing device provide fully automated processing with unwavering quality levels.

Quality is built into every facet of the VHybrid 260 and Vollmer demonstrates this with its innovative ‘wall concept’ that provides the highest possible rigidity and vibration damping through its concrete polymer foundation. This is complemented by the effective spindle and motor cooling technology that creates greater thermal stability for unparalleled precision and power while the vertical spindle configuration eradicates issues related to fixing and floating bearings.

Automation and ease-of-use are factored into every element of the new VHybrid 260 and this includes the tool loading and unloading facilities. Here, Vollmer offers several options with its HC4 chain magazine that has space for 39 HSK-63A tools or up to 158 shank-type tools with a maximum weight of 5kg.

Alternatively, for manufacturers producing larger tools, Vollmer offers the HC4 Plus, which provides space for 160 shank type tools or 40 HSK-63A tool holders with a tool diameter of 80mm. With larger tool diameters of up to 150mm, there is space for 20 HSK-63A tool holders with a maximum weight for individual tools up to 10kg.

Further demonstrating that Vollmer has factored ease-of-use and automation into all areas of the five-axis VHybrid 260, the automation options also extend to the eight-tool grinding wheel changer that ensures the right grinding wheel for the right tool is always supplied to the work envelope with no manual intervention. As an option, coolant nozzles can be automatically exchanged with the wheelsets on both spindles.

Vollmer has combined this with a multi-function handwheel for easy axis adjustment, simple touchscreen control, optimal machine access and height-adjustable tilting control platform.

The machine also comes with modularly designed ExLevel PRO software that allows efficient, fast and easy machining of a wide range of tools in both grinding and eroding operations. Simplicity of use extends to tool simulation that can be set up directly at the machine or remotely.

Optional extras include linear scales on all axes for even greater precision levels and performance plus a steady rest to optimise grinding results when processing longer cutting tools that have the potential to deflect. Vollmer also offers automated gripper compensation as an in-process solution, which provides maximum precision when loading and unloading tools and reduction sleeves and it also reduces wear and maximises stability.