BCN3D

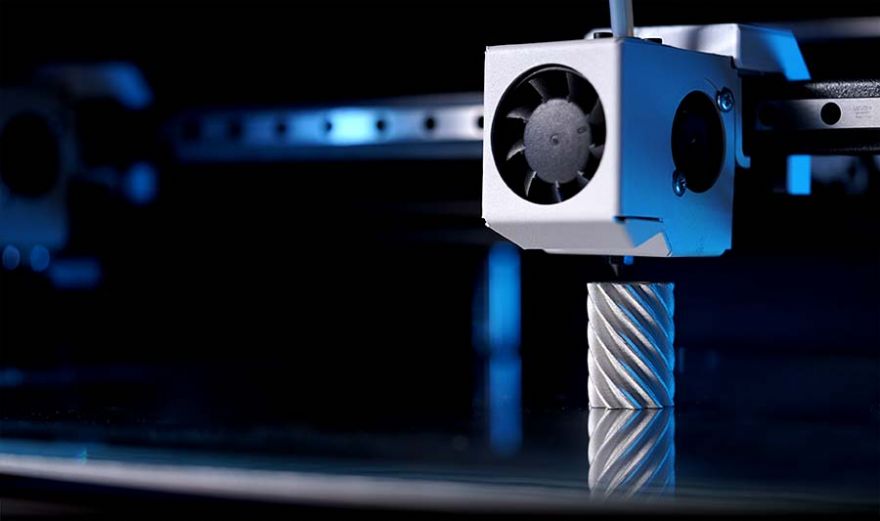

BCN3D, a leading 3-D printing solutions manufacturer, has launched its Metal Pack - containing Ultrafuse Metal Filaments developed by Forward AM — for its line of Epsilon Series 3-D printers.

The development allows its customer base to easily upgrade their hardware to catch up with the latest developments and affordably produce solid metal parts. The upgrade opens up a new range of applications for BCN3D customers, especially for spare parts, functional prototyping, and tooling, and is mainly aimed at the pharmaceutical, food, automotive, aerospace, and manufacturing sectors.

The parts produced by this process have practically identical behaviour to those produced by metal injection moulding or CNC, and offer an office-friendly solution with far more design freedom.

The Metal Pack includes both Ultrafuse 316L and 17-4 PH, and a new exclusive hot-end for metal, as well as specific accessories, to ensure a smooth 3-D printing experience. Debinding and sintering can be carried out externally through the Forward AM authorised network of service suppliers.

Eric Pallarés, CTO of BCN3D, said: “The whole AM industry is chasing metal 3-D printing. But the truth is that, nowadays, affordable available solutions, if any, are very scarce. With the release of the Metal Pack at BCN3D, we are excited to leverage BASF’s decades of experience in MIM technology applied to metal extrusion and post-processing.”

End-to-end and accessible solution He continued: “In combination with our existing 3-D printing ecosystem, it becomes an end-to-end and accessible solution for functional prototyping. Our customers will be able to take the best advantage of 3-D printing by obtaining industry-grade metal parts, within days.”

Firat Hizal, head of the Metal Systems Business Group at BASF 3-D Printing Solutions GmbH, said: “The Ultrafuse Metal Filaments portfolio has been developed based on BASF´s decades of know-how coming from the MIM industry.

“Filaments are designed for ultimate ease of handling and can be used on any open-source Fused Filament Fabrication (FFF) printer. We are very happy that both Ultrafuse 316L and 17-4 PH are validated by BCN3D and the company decided to enable its user base by introducing this bundle.”

The printing process is divided into three steps: printing a part with the BCN3D Epsilon 3-D printers, followed by industry-standard debinding and sintering, which is done externally through the current Forward AM authorised network of suppliers. The result is a final part which is nearly 100% solid stainless steel.

For the printing process, filaments Ultrafuse 316L and 17-4 PH contain high levels of stainless steel in combination with polymer binders which allows for easy printing. The binder content from the printed part is removed in a catalytic debinding process. The next step is the part undergoing a subsequent sintering process at temperatures right below the melting temperature of the metal which causes the metal particles to coalesce. The material then reaches its final properties through post-sintering. For example, achieving required performances in aspects such as hardness and strength.

The Metal Pack will include one Ultrafuse 316L (3kg) spool and one Ultrafuse 17-4PH (3kg), the Magigoo 316L which is also compatible with the 17-4PH, two new Hotend M’s and the new BCN3D Brass Wipers for Metal.

BCN3D will also publish an add-on for new slicing software BCN3D Stratos dedicated to printing with metal that will include printing profiles curated for the company’s Epsilon Series.

The first units of the Metal Pack will be shipped in January 2022.