Visual Components

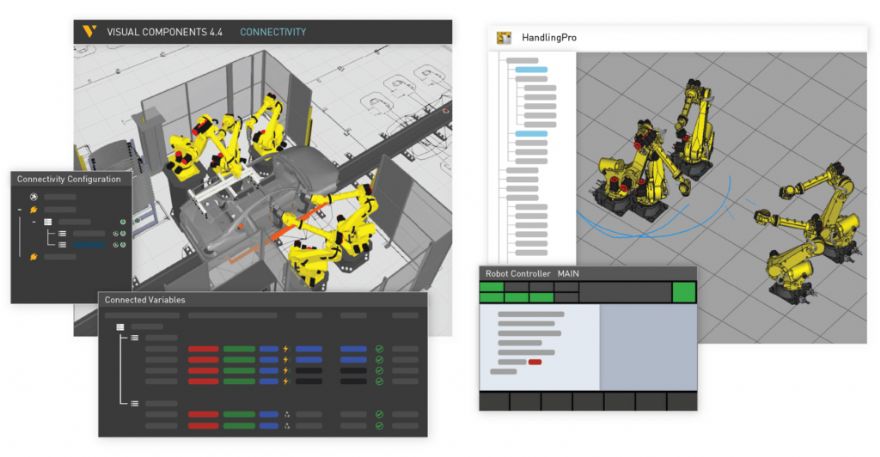

Visual Components has released version 4.4 of its 3-D simulation software for manufacturers, system integrators and machine builders. The upgrade features virtual commissioning, faster simulation set-ups and a more streamlined experience for end users.

The latest version makes it easier for manufacturers to design and visualise digital twins and use simulation models for virtual commissioning. This can, for example, help organisations streamline robot programming and commissioning tasks with all simulation tools in one place. 2-D drawings from Autodesk can also be converted to 3-D layouts faster with the use of the CAD Attribute Reader, accelerating designs from scratch.

Mikko Urho, CEO at Visual Components, said: “Visual Components 4.4 is a truly exciting product release for professionals in the manufacturing space and is part of our commitment to help our customers plan their systems better. Our already powerful simulation solution has been upgraded to better meet the needs of manufacturers in a digital sector defined by Industry 4.0.”

The new version provides compatibility to offer a native connection to Fanuc robots, one of the most widely used robot brands. Simulations can be connected directly to Fanuc’s virtual and physical robot controllers via a communications medium such as Fanuc PC Developer’s Kit or Robot Server Package.

More accurate cycle timesValidation of programs is possible with more accurate cycle times and robot paths, plus the ability to remotely monitor the performance of manufacturing systems and even use virtual reality (VR) to collaborate and communicate programs with peers and customers.

Also included in the new release is the addition of Python APIs to Process Modelling to help simplify tasks and avoid repeated manual work. Product Assembly Creator API allows scripts to be imported, helping create functional and simulation-ready 3-D product assemblies within seconds.

Improvements to Process Modelling resources mean that dynamic object avoidance, collision scanning and improved decision-making for speed adjustments are available to system integrators.

On top of these benefits, Visual Components 4.4 also allows system integrators to assign product routing rules for different product types, with ‘Process Statements’ also able to support product position properties, allowing for easy adjustment of product location and orientation. New statements have been added to robot programming to facilitate greater flexibility, better application of control flow logic and improved overall experience.

The manufacturing industry can also benefit from UI improvements to the software, helping the connectivity of elements to be managed with virtual commissioning applications. Enhancements made to the IO configuration allows for improved UI for searching, pairing and unpairing variables.

Further to this the new Visual Components Experience version 1.6 enables virtual reality (VR) improvements, more adaptable controls, a measuring tool and Point Cloud Support in VR, all of which can improve collaboration on projects, preparation for impressive project proposals, as well as helping to accelerate sales cycles for users.