On the Haas Schleifmaschinen stand at the recent

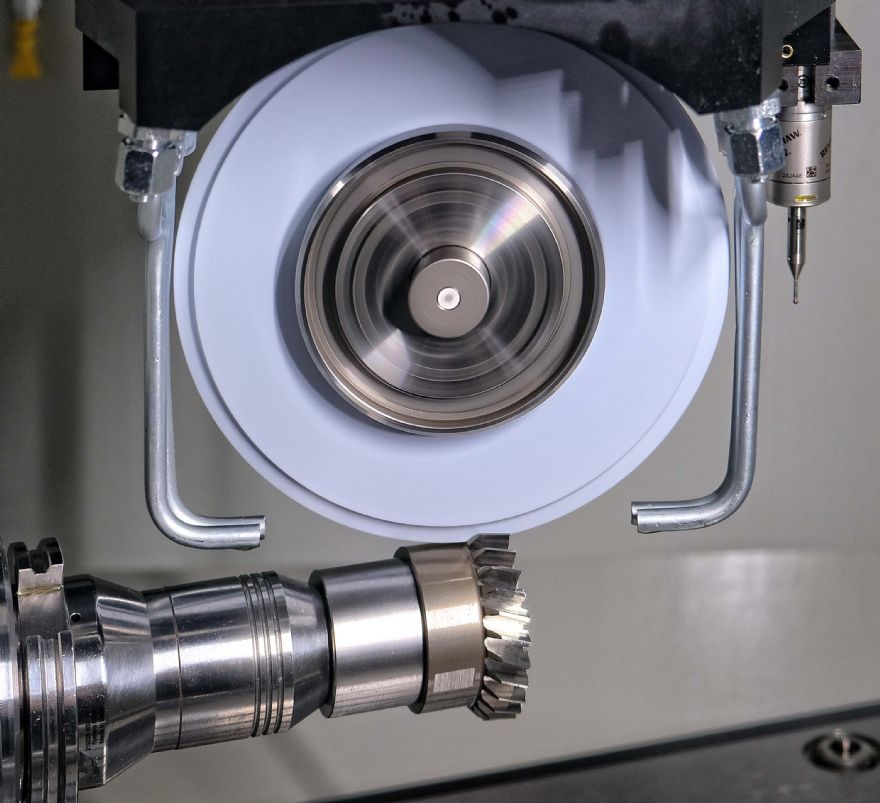

EMO 2021 exhibition in Milan, the grinding machine manufacturer demonstrated on one of its Multigrind machine platforms the single-point grinding of a skiving tool to such close tolerances that it is able to produce gears to quality 2 to 3 — the accuracy class when skiving gears is traditionally 4 to 6.

Sole sales and service agent for Haas Schleifmaschinen in the UK, Ireland and the Middle East, is Hampshire-based

Kingsbury.

Wolfram Hermle, Haas Schleifmaschinen software department manager, said, "Today, dimensional tolerances of 2µm are not uncommon. The production of such accurate profiles requires highly complex calculations — if we want to have that under control, we have to do the math ourselves."

Two years ago, when the project to develop the required software was initiated, there was no satisfactory method on the market for determining machining cycles to achieve the ever-increasing gear precision being demanded by industry. The goal was to create a system for calculating cycles for machining the wide variety of gears that need to be produced.

Mr Hermle does not want to divulge details of the newly developed calculation model in Haas Schleifmaschinen”s Multigrind Horizon software, but confirms that gears of accuracy class 2 to 3 can be achieved. However, he pointed out that it is only one element of the process, the other being the high precision the grinding machine must be capable of achieving. Alignment of the grinding wheel must be accurate to 0.0001 degree.

Crucial to achieving the desired grinding performance are continuous dressing of the grinding wheel and high-level measuring technology, with constant automatic workpiece measurement and closed loop compensation of errors.

Mr Hermle concluded: “As far as I know, this accuracy is achieved exclusively using Haas Schleifmaschinen production solutions. Only when software and hardware are perfectly matched can a skiving tool be created for manufacturing a perfect gear.”