Starrag’s

Starrag’s new online Fingerprint machine analysis service enables remote Starrag service technicians to quickly record machine conditions and, within 24hr, provide customers with detailed overviews of the degree of wear on their machines’ mechanical assemblies.

In addition to help prevent unplanned wear-related failures — and improve machine availability and productivity to therefore reduce workpiece costs — Fingerprint also saves on maintenance costs and enables repairs to be planned.

Offered as the latest digital tool in Starrag’s renowned customer service strategy, Fingerprint is a very cost-effective way to determine a machining centre’s overall condition. The machine is out of production for only 1hr and, without the need for extensive disassembly/assembly work, the result is a fast and meaningful analysis of the main components’ state of wear.

Originally launched last year for users of modern Heckert machines with Siemens CNC control, the service is now gradually being rolled out across other Starrag machine ranges — after a baseline survey with the initial machine commissioning, it is recommended that Fingerprint is carried out quarterly. Such frequency will not only allow continual changes and wear to be observed, but a history of the machine’s condition over its life cycle can also be useful information if the machine is later sold, according to Starrag.

An unscheduled Fingerprint is also possible, which is ideal after a crash during set-up, for example, “when the customer cannot see any possible damage but wants to err on the side of caution”.

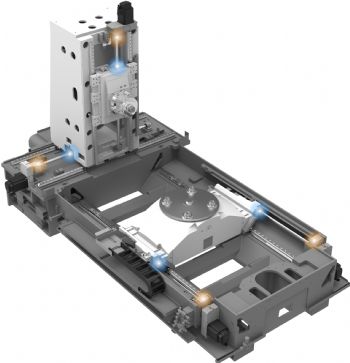

The Fingerprint service includes: frequency response analyses on all processing axes for monitoring the drive mechanisms (ballscrews, toothed belts) and for identifying resonance points; vibration analysis of the work spindles to determine bearing condition and wear; a circularity test for checking the passage of squares and static friction; measurement of the current consumption of all processing axes; and determining the degree of contamination and wear of the linear measuring systems as well as meter readings and temperature data.

The information is evaluated within a few hours using comparative data and, by the next working day at the latest, the customer receives a report that breaks down all the conditions and, if necessary, includes suggestions on how to eliminate errors or information about maintenance work.

An ‘on site’ Fingerprint is also available by a Starrag service technician, who can also carry out further investigations such as additional geometric and thermal measurements.