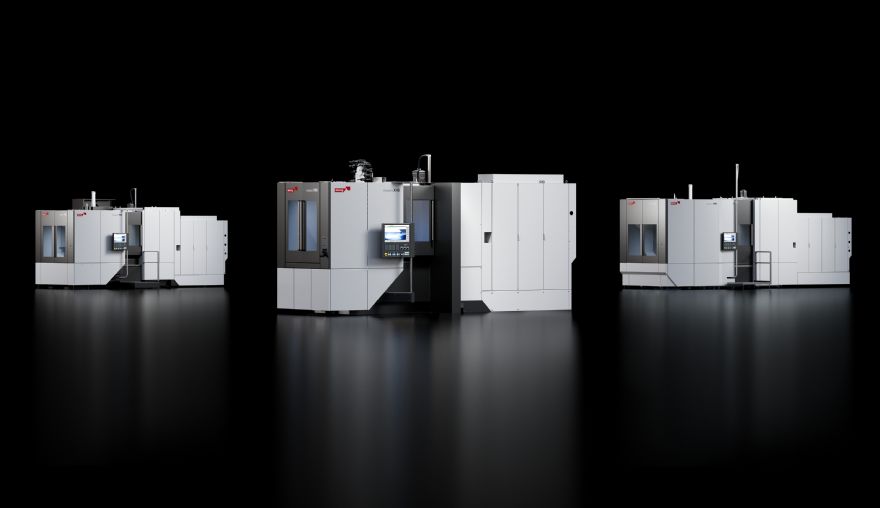

Starrag Heckert

Starrag Heckert has introduced its new H Compact Series of horizontal machining centres (HMCs) that will appeal to manufacturers of all sizes. The benefits of HMCs can sometimes be overshadowed by the sizeable footprint of the machines in comparison to their vertical counterparts - with the H Compact Series, Starrag Heckert delivers the benefits of a horizontal within a compact footprint.

Lee Scott, director of sales and applications at Birmingham-based Starrag UK Ltd, said: “They are compact HMCs which denote the ‘H’ and they are fitted with a trunnion table with five-axis capability that provides an impressive X-axis range. We can also incorporate a high-speed table on the machine for turning - this alternative configuration gives us the ‘T’ range.

“In its basic guise, it is a twin pallet HMC with a monobloc mineral cast material base that is very vibration-absorbent and also very stiff. The machine design is like a giant bathtub where all the chips fall straight out of the work area and take all of the heat with them. The column then sits on the base with linear rails and a direct measuring system across the whole of the machine that delivers exceptional accuracy and optimal cutting conditions.”

The machine column has positive leveraged ratios that are credited to maximum guideway distances and also weight compensation that improves performance, accuracy and efficiency of the Y axis that is driven by ballscrews. Alluding to the pallet system on the new series, Mr Scott said: “It is a twin pallet machine and the surface of the pallets are ground, so the interfaces are perfect for the fixturing, whether it be on a trunnion or a standard B axis.

“Outside of the machine, we then have the set up station. So, while the first pallet is working inside the machining area, the second pallet is either loaded by a robot, a flexible manufacturing system (FMS) or an operator. After all, if the spindle isn’t cutting, the machine isn’t making any money.”

The new HMC has a complete range of spindles available. This includes a 30,000rev/min spindle offering for cutting aluminium, high-torque or geared spindles for machining titanium as well as quill spindles for extended reach — there is a spindle for every application.

Referring to the tool magazines that feed the spindle, Mr Scott added: “The tool magazines start with a single magazine, and we can also run a parallel system with up to a total of 450 tools on this machine frame. You also have to get rid of the chips. This machine can create huge volumes of aluminium swarf that have to go through the machine and out to a swarf system, here the machine frame design has been optimised to remove chips from the work area at high speed.”

Taking a closer look at the operator interface on the new H Compact Series, the machine incorporates the latest Fanuc or Siemens CNC control unit. Mr Scott continued: “Operators love our system, it has a touchscreen and multi-screen facility that offers the perfect solution for all engineers that really want to get that maximum amount of data from the machines.

“The control system offers a variable screen layout that can display between one and three applications and allows for a parallel display of information with context-sensitive user guidance through the colour/brightness of the control elements. Furthermore, the system offers easy integration of third-party applications and/or VPN technology.”

As an automation-friendly solution, the new H Compact Series caters for customers with a wide range of options and interfaces to present maximum flexibility. Together with systems partners like Fastems, Starrag can offer FPC and FPT modules as well as integration with robots, gantry loading cells and interlinking machines from a single source.