Due to the exacting precision requirements of the components it manufactures and the nature of the materials it machines, including Inconel and titanium, the

Oxford Engineering Group employs a wide range of advanced machine tools, as highlighted by the recent installation of two new turning centres at Bicester-based

Hutton Precision Engineering — a Doosan MX2600ST and a Doosan MX2600, which offer efficient turning and milling, with fewer set-ups, fewer machining operations and shorter cycle times.

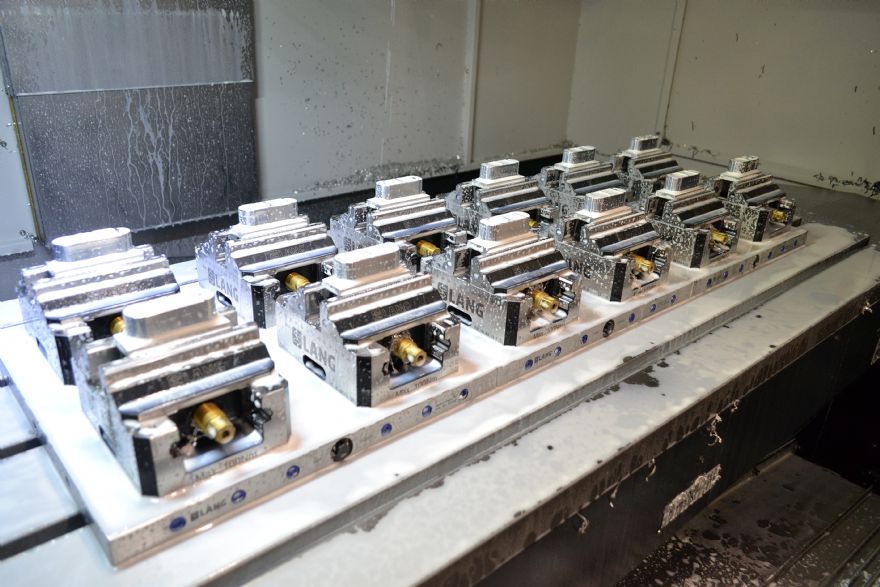

In a similar vein, to optimise the efficiency of a Doosan vertical machining centre so that it could produce the required volumes of high-precision parts, Hutton Engineering bought a stamping unit, 24 Makro-grip five-axis vices and a wide range of vice jaws from Buckinghamshire-based

Lang-Technik UK Ltd.

Wayne Bosher, Hutton Engineering’s workshop manager, said: “We were aware of the reputation of Lang-Technik’s products and were convinced that the use of the company’s work-holding systems would further improve our productivity levels while delivering a range of advantages related to securely holding ‘exotics’ when machined under heavy loads. In addition, Lang-Technik work holding has increased our efficiency levels as its quick set-up times have minimised machine downtimes.

“By using our new stamping unit before inserting a workpiece blank into a Makro-grip five-axis vice, we can make precise indentations in it; and because the projections on the jaws of our new vices precisely engage with the pre-stamped indents, we can achieve maximum workpiece holding power with the bonus of only needing to apply minimal clamping forces.

“As the purpose of our Makro-grip five-axis vices is to simply hold the workpiece with minimum pressure applied, we can hold both soft and hard materials without fear of deformation or other problems. The use of the Lang-Technik system has improved our process reliability and significantly increases our machining efficiency levels.”

Pre-stamping benefitsLang-Technik says its pre-stamping technology, in conjunction with the company’s Makro-grip five-axis vices, differs “fundamentally from the clamping methodologies of other work-holding manufacturers and has grown to be regarded as the benchmark clamping method for secure five-axis machining.

“The serrated jaws of conventional vices must fulfil two separate functions; in addition to indenting workpieces’ material, they must also securely hold the workpiece. As conventional vices are only able to exert a maximum pressure of about 4-6 tonnes, the effective penetration of their serrated jaws into workpiece materials represents a real challenge, especially when clamping harder materials.”

The company added: “To ensure that the workpiece is penetrated correctly, the teeth of a conventional vice’s serrated jaws must remain sharp to be effective. As these teeth are subjected to high levels of wear their clamping ability is liable to decline. Also, when using conventional vices during the machining of soft, distortion-prone materials, jaws’ teeth can lose their holding power as they are inclined to work free of the workpiece when subjected to machining forces.

“The use of our stamping technology overcomes these problems by applying up to 20 tonnes of pressure during pre-stamping, ensuring the creation of precise indentations, even when this procedure is carried-out on hard materials with tensile strengths of up to 1,500N/mm

2.”

Following pre-stamping only low clamping pressure is required to hold a workpiece securely as the teeth of the five-axis vice engage precisely with the pre-stamped indents, allowing the use of vices with a relatively compact design — and the elimination of wear on clamping teeth.

Moreover, in addition to securely holding the workpiece in the vice under the most severe machining conditions, the truncated pyramid shapes of the pre-stamped indents prevent clamping teeth from impacting deeper into the workpiece by providing a ‘defined penetration limit’.

The use of Lang-Technik’s pre-stamping technology and Makro-grip five-axis vices has a major advantage when conventional machine vices reach their limits in terms of material hardness.

“Despite the application of low clamping pressure, the clamping forces exerted on a workpiece in a Makro-grip five-axis vice actually become higher the harder and more resistant the material being machined is. Also, as workpieces are prepared outside of the machine tool downtime is considerably reduced.”

The success of the initial Lang-Technik system is now seeing it being used on all of Hutton Engineering’s main milling machines and machining centres. Furthermore, Hutton Engineering’s sister company, Oxford Engineering, is now using this clamping system on its medium-size machines.

This commonality of work-holding systems also helps with the interchangeability of parts between the companies and provides an additional capability to respond to changes in customer demand.