John Harland (left), managing director of Westley Engineering with Paul Proctor, machine shop manager

John Harland (left), managing director of Westley Engineering with Paul Proctor, machine shop managerFounded in 1998 as a spin-off from the prestigious gunmaker Westley Richards,

Westley Engineering has evolved far beyond its origins. While only 5% of its output now relates to gun components, the company has established itself as a trusted supplier of machined components and assemblies to multiple sectors including aerospace, automotive, rail, white goods and renewable energy.

Aerospace is its largest market, accounting for 45% of total production by value. A notable aerospace contract involves the manufacture of rotor clips used within aircraft disc brakes. Made from aerospace-grade steel and Inconel, the components are used in both civil and military aerospace programmes. Demand for these clips has risen significantly over the last few years.

Three years ago, Westley Engineering improved the accuracy of the manufacturing process by switching from piercing holes in the clip on press tools to drilling them on a 40-taper vertical machining centre (VMC). Although it improved the precision, it also increased cycle times substantially and made the process more labour intensive.

So in late 2023, the company installed a Brother Speedio S700Xd1 four-axis, 30-taper machining centre, followed by a second in April 2025. Supplied by

Whitehouse Machine Tools, the exclusive UK and Ireland distributor for the Japanese manufacturer, these high-speed machines have now replaced the VMC for production of the clips.

New machine is a ‘gamechanger’John Harland, managing director of Westley Engineering, said: “The arrival of the first Brother machine was a gamechanger. Its exceptional speed, especially the 0.7sec tool changes, means each Speedio can machine clips 35 to 40% faster than with our previous setup.

“The former VMC ran around the clock on weekdays and through the weekend. The new Speedios not only handle the entire production volume more efficiently, but also offer extra capacity for future growth.”

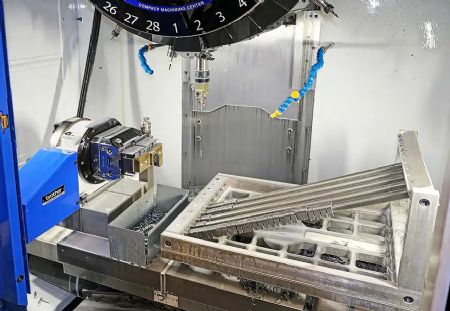

Pictured right: the machining area of one of the Brother Speedio S700Xd1 30-taper machining centres on the shopfloor at Westley Engineering’s Birmingham factory. It shows the fixture (right) with multiple inclined bars holding the brake clips, allowing hundreds of them to be presented for drilling and countersinking in one hit before the machine doors are opened again

Pictured right: the machining area of one of the Brother Speedio S700Xd1 30-taper machining centres on the shopfloor at Westley Engineering’s Birmingham factory. It shows the fixture (right) with multiple inclined bars holding the brake clips, allowing hundreds of them to be presented for drilling and countersinking in one hit before the machine doors are opened againIn partnership with Whitehouse Machine Tools, Westley Engineering implemented an automated, single-operation process on each Speedio. The new production route features custom-built fixtures with nine inclined bars, each capable of holding about 36 clips. This high-density arrangement enables over 300 parts to be machined per cycle, significantly more than the flat fixtures used previously.

Cycle times have been reduced to between 2 and 3min per clip, depending on the variant. For example, the Inconel version requires additional milling on the outer arms, whereas the steel variants do not. Typical batch size ranges from 5,000 to 10,000 units.

coolant-actuated gripperBefore deployment, the process was validated at Whitehouse Machine Tools’ Kenilworth technical centre. Its applications engineers wrote the machine programs, assisted with fixture setup and provided on-site training, all offered as part of the supplier’s lifetime service and support. A coolant-actuated gripper, housed in one of the Speedio’s 28 turret positions, picks up each clip from the inclined bars. After verifying the workpiece position using sensors, the gripper transfers the part to a Schunk hydraulic vice mounted on a rotary axis.

The component is then machined — drilled, countersunk and in some cases milled — before being dropped into a container for post-processing. All clips undergo 100% inspection, including after heat treatment, followed by fettling as needed to correct any distortion.

Mr Harland noted: “Scrap has dropped to under 1%, down from up to 4% with the old process; and thanks to the energy efficiency of the Brother machines, we have cut power consumption by an estimated 60%.”